Free sample for Manufacturer Linear Guide with Block for CNC Router Machine and 3D Printer

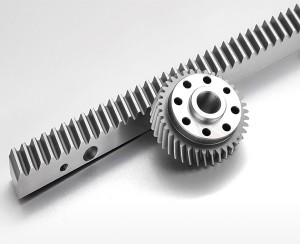

High precision rack and pinion

- PYG manufacturing Base is equipped with leading domestic NC machining equipment

- Fully modern equipment and management system

- Strict control of production and manufacturing links

- Leading international technical standards

- Fine process manufacturing to ensure that products have the world's leading level

The rack is a transmission component, mainly used to transfer power, and generally matched with the gear into the rack and pinion drive mechanism, the reciprocating linear motion of the rack into the rotary motion of the gear or the rotary motion of the gear into the reciprocating linear motion of the rack. The product is suitable for long distance linear motion, high capacity, high precision, durable, low noise and so on.

The application of rack:

mainly used in various mechanical transmission systems, like Automation Machine, CNC Machine, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works and so on.

![]()

Specifications of gear rack and pinion

Helical gear rack:

Helical angle: 19°31’42’

Pressure angle: 20°

Precision grade: DIN6/ DIN7

Hardness treatment:Tooth surface high frequency HRC48-52°

Production process:four side grinding,tooth surface grinding.

![]()

![]()

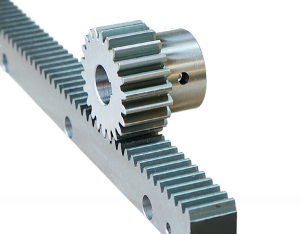

Straight gear rack:

Pressure angle: 20°

Precision grade: DIN6/ DIN7

Hardness treatment:Tooth surface high frequency HRC48-52°

Production process:four side grinding,tooth surface grinding.

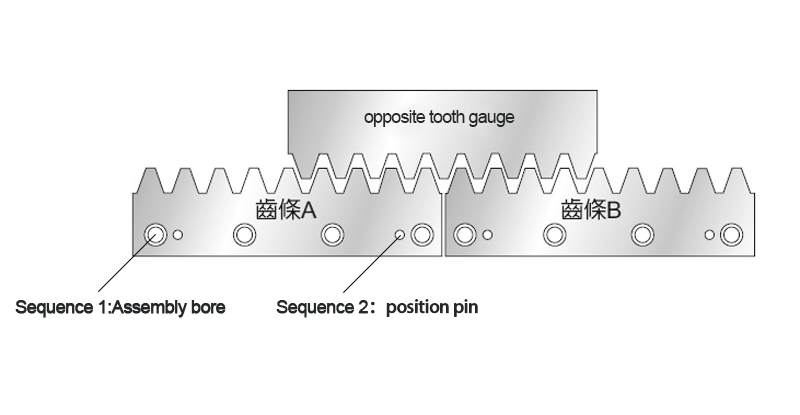

Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

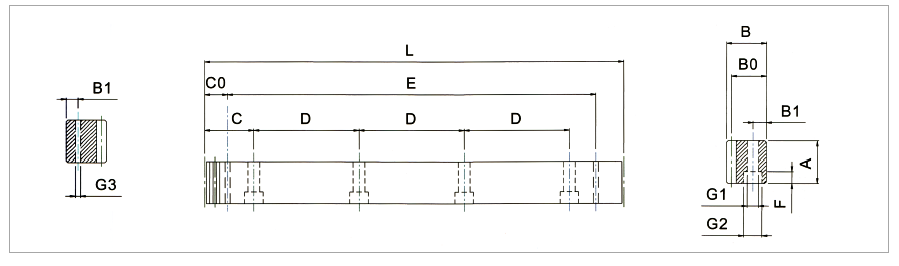

Technical Parameter

Straight Teeth System

① Precision grade: DIN6h25

② Tooth hardness: 48-52°

③ Tooth processing: Grinding

④ Material: S45C

⑤ Heat treatment: High frequency

| model | L | Teeth NO. | A | B | B0 | C | D | Hole NO. | B1 | G1 | G2 | F | C0 | E | G3 |

| 15-05P | 499.51 | 106 | 17 | 17 | 15.5 | 62.4 | 124.88 | 4 | 8 | 6 | 9.5 | 7 | 29 | 441.5 | 5.7 |

| 15-10P | 999.03 | 212 | 17 | 17 | 15.5 | 62.4 | 124.88 | 8 | 8 | 6 | 9.5 | 7 | 29 | 941 | 5.7 |

| 20-05P | 502.64 | 80 | 24 | 24 | 22 | 62.83 | 125.66 | 4 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 |

| 20-10P | 1005.28 | 160 | 24 | 24 | 22 | 62.83 | 125.66 | 8 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 |

| 30-05P | 508.95 | 54 | 29 | 29 | 26 | 63.62 | 127.23 | 4 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 |

| 30-10P | 1017.9 | 108 | 29 | 29 | 26 | 63.62 | 127.23 | 8 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 |

| 40-05P | 502.64 | 40 | 39 | 39 | 35 | 62.83 | 125.66 | 4 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 |

| 40-10P | 1005.28 | 80 | 39 | 39 | 35 | 62.83 | 125.66 | 8 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 |

| 50-05P | 502.65 | 32 | 49 | 39 | 34 | 62.83 | 125.66 | 4 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 |

| 50-10P | 1005.31 | 64 | 49 | 39 | 34 | 62.83 | 125.66 | 8 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 |

| 60-05P | 508.95 | 27 | 59 | 49 | 43 | 63.62 | 127.23 | 4 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 |

| 60-10P | 1017.9 | 54 | 59 | 49 | 43 | 63.62 | 127.23 | 8 | 16 | 18 | 26 | 17 | 31.4 | 955 | 15.7 |

| 80-05P | 502.64 | 20 | 79 | 71 | 71 | 62.83 | 125.66 | 4 | 25 | 22 | 33 | 21 | 26.6 | 449.5 | 19.7 |

| 80-10P | 1005.28 | 40 | 79 | 71 | 71 | 62.83 | 125.66 | 8 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 |

Our Service:

1. Competitive price

2. High quality products

3. OEM service

4. 24 hours online service

5. Professional technical service

6. Sample available

1. Before placing order, welcome to send us inquiry, to describe simply your requirements;

2. Normal length of linear guideway from 1000mm to 6000mm, but we accept custom-made length;

3. Block color is silver and black, if you need custom color, such as red, green, blue, this is available;

4. We receive small MOQ and sample for quality test;

5. If you want to become our agent, welcome to call us +86 19957316660 or send us email.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

TOP

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu