Good Quality Hot Sale samall Linear Bearing for miniature equipment

Our company give priority to high quality and customer fulfillment and for this we follow stringent good quality control measures. We have now in-house testing facilities where our goods are tested on every single aspect at different processing stages. PYG owning to latest technologies, we facilitate our shoppers with custom made manufacturing facility. Welcome to visit our company and factory, there are various items displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to supply you the best service

PMGW Wide Linear Rail

1. convenient installation

2. complete specifications

3. adequate supply

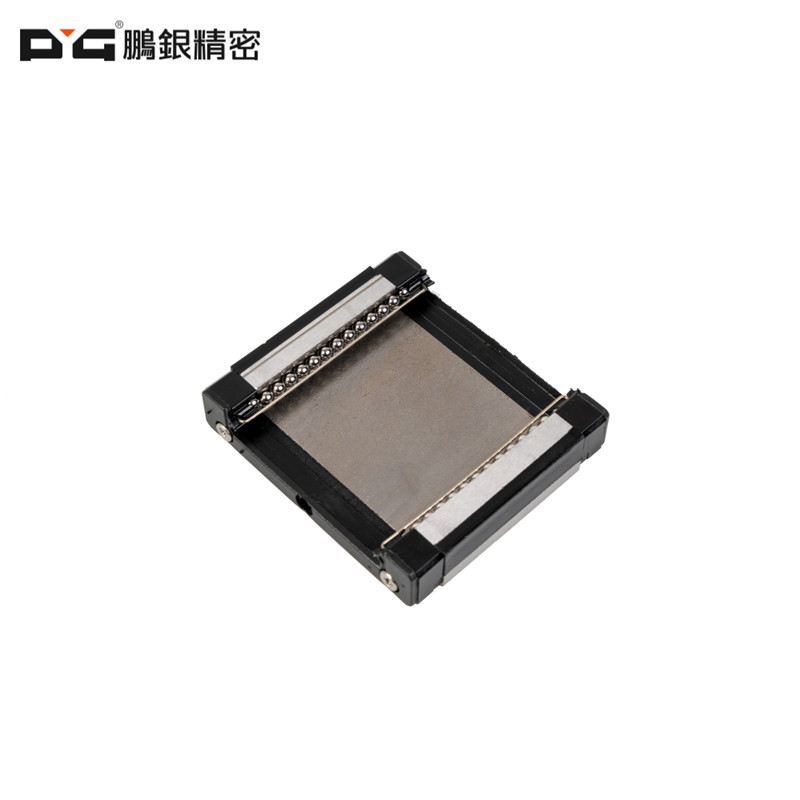

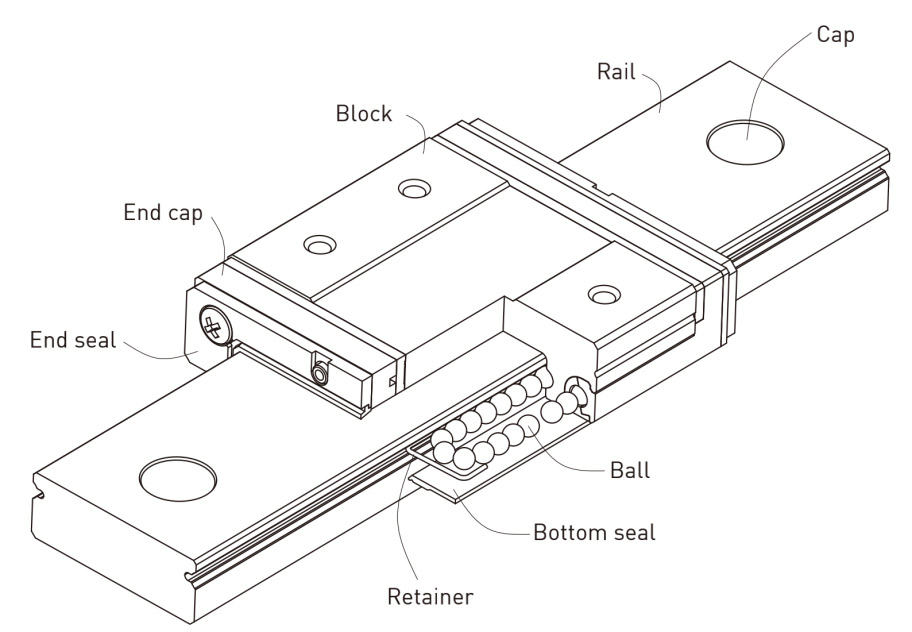

1. Rolling system

block, rail, end cap, steel balls, retainer

2. Lubrication system

PMGN15 has grease nipple, but PMGN5, 7, 9,12 need to be lubricated by the hole at the side of the end cap

3. Dust proof system

scraper, end seal, bottom seal

Characteristic for miniature linear motion

1. widened mini linear slide design improve largely torque load capacity.

2. adopts Gothic four points contact design, can bear high load from all directions, high rigidity and high precision.

3. has balls retainer design, also can be interchangeable.

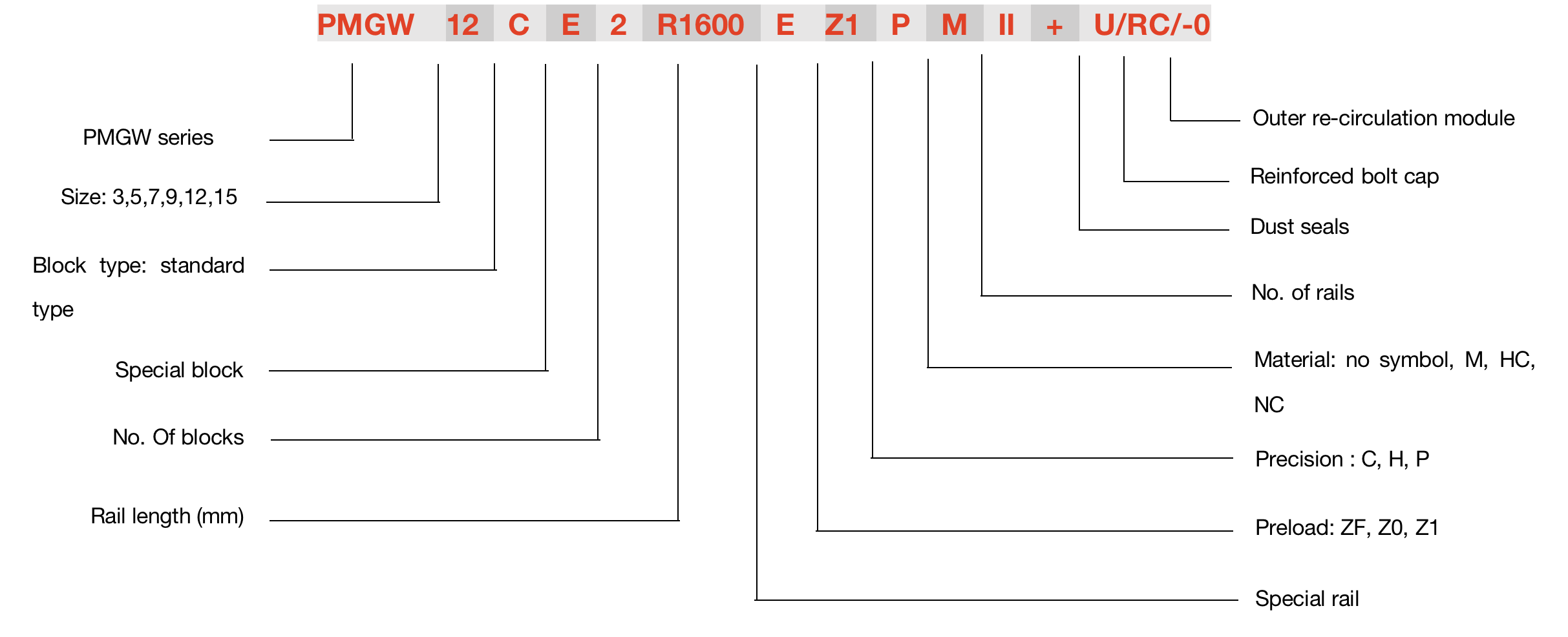

Code Meaning for Miniature Ball Bearing Carriages and Guide Rails

we take model 12 for example

PMGW block and rail type

|

Type |

Model |

Block Shape |

Height (mm) |

Rail Length (mm) |

Application |

| Flange type | PMGW-CPMGW-H |

|

4 ↓ 16 |

40 ↓ 2000 |

PrinterRoboticsPrecision measure equipmentSemiconductor equipment |

Application for Mini Linear Bearing

PMGW linear guides application include: semi-conductor machine, printing electric board IC assembly equipment, medical equipment, mechanical arm, precision measurements, official automation machine and other miniature linear guides.

Precision Level

miniature linear guide rail precision includes: Normal ( C ), High ( H ), Precision ( P )

Preload

miniature linear guide has Normal, Zero and Light preload, see below table:

| Preload level | Mark | Preload | Precision |

| Normal | ZF | 4~10 um | C |

| Zero | Z0 | 0 | C-P |

| Light | Z1 | 0.02C | C-P |

Dust Seals

For normal miniature linear bearings, we install oil scrappers on both ends of block to avoid the dust or particles into the inside of block to affect the service life time and precision. The dust seals are installed under the block to avoid the dust or particles into the block from bottom, if clients want to choose the dust seals, can add +U after the miniature guide rails model.

See below table for installation space :

| Model | Dust Seals | H1 mm | Model | Dust Seals | H1 mm |

| MGN 5 | - | - | MGW 5 | - | - |

| MGN 7 | - | - | MGW 7 | - | - |

| MGN 9 | • | 1 | MGW 9 | • | 2.1 |

| MGN 12 | • | 2 | MGW 12 | • | 2.6 |

| MGN 15 | • | 3 | MGW 15 | • | 2.6 |

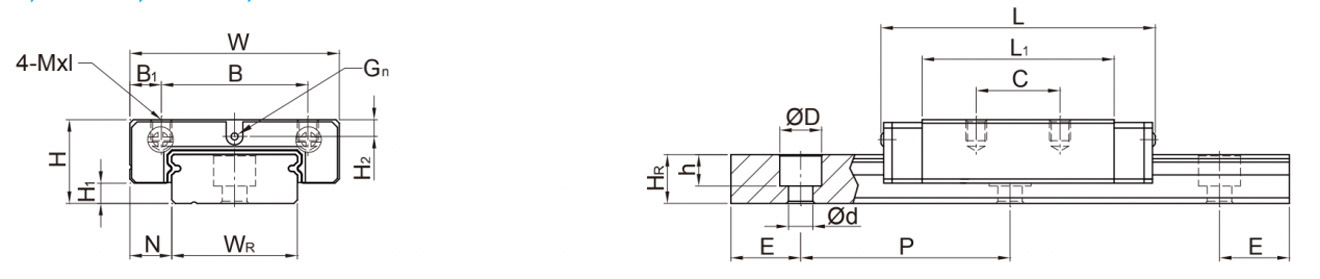

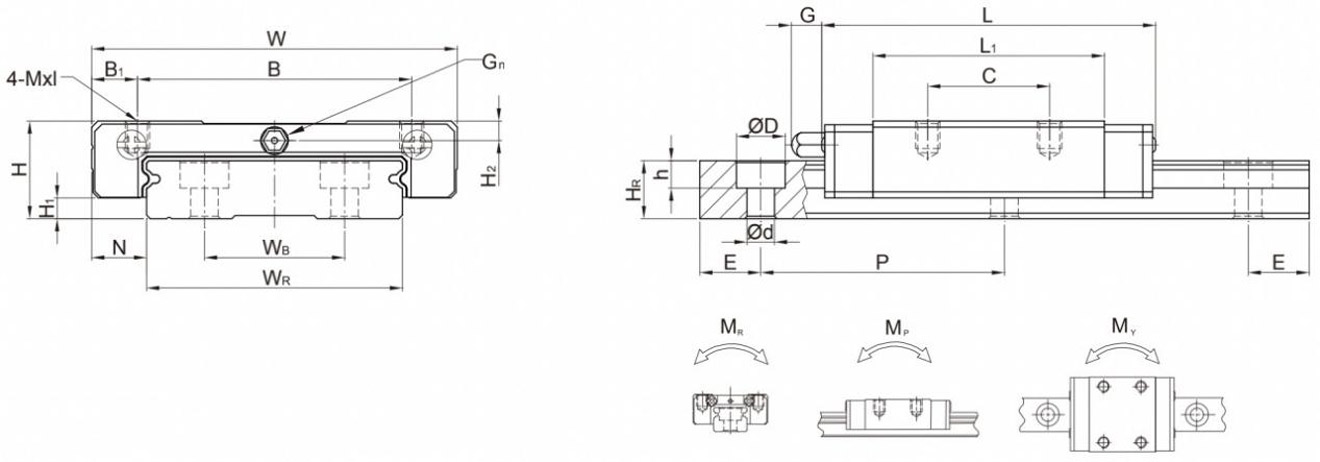

Dimensions

Complete dimensions for all mini linear slide rails size see below table or download our catalog:

PMGW7, PMGW9, PMGW12

PMGW15

| Model | Dimensions of Assembly (mm) | size of block (mm) | Mounting bolt size for rail | Mounting bolt for rail | Basic dynamic load rating | Basic static load rating | Allowable static rated moment | weight | ||||||||||||||||||||||

| MR | MP | MY | Block | Rail | ||||||||||||||||||||||||||

| H | H1 | N | W | B | B1 | C | L1 | L | G | Gn | Mxl | H2 | WR | WB | HR | D | h | d | P | E | mm | C (kN) | C0(kN) | N-m | N-m | N-m | kg | Kg/m | ||

| PMGW7C | 9 | 1.9 | 5.5 | 25 | 19 | 3 | 10 | 21 | 31.2 | - | Φ1.2 | M3*3 | 1.85 | 14 | - | 5.2 | 6 | 3.2 | 3.5 | 30 | 10 | M3*6 | 1.37 | 2.06 | 15.7 | 7.14 | 7.14 | 0.02 | 0.51 | |

| PMGW7H | 19 | 30.8 | 41 | 1.77 | 3.14 | 23.45 | 15.53 | 15.53 | 0.029 | |||||||||||||||||||||

| PMGW9C | 12 | 2.9 | 6 | 30 | 21 | 4.5 | 12 | 27.5 | 39.3 | - | Φ1.2 | M3*3 | 2.4 | 18 | - | 7 | 6 | 4.5 | 3.5 | 30 | 10 | M3*8 | 2.75 | 4.12 | 40.12 | 18.96 | 18.96 | 0.04 | 0.91 | |

| PMGW9H | 23 | 3.5 | 24 | 38.5 | 50.7 | 3.43 | 5.89 | 54.54 | 34 | 34 | 0.057 | |||||||||||||||||||

| PMGW12C | 14 | 3.4 | 8 | 40 | 28 | 6 | 15 | 31.3 | 46.1 | - | Φ1.2 | M3*3.6 | 2.8 | 24 | - | 8.5 | 8 | 4.5 | 4.5 | 40 | 15 | M4*8 | 3.92 | 5.59 | 70.34 | 27.8 | 27.8 | 0.071 | 1.49 | |

| PMGW12H | 28 | 45.6 | 60.4 | 5.1 | 8.24 | 102.7 | 57.37 | 57.37 | 0.103 | |||||||||||||||||||||

| PMGW15C | 16 | 3.4 | 9 | 60 | 45 | 7.5 | 20 | 38 | 54.8 | 5.2 | M3 | M4*4.2 | 3.2 | 42 | 23 | 9.5 | 8 | 4.5 | 4.5 | 40 | 15 | M4*10 | 6.77 | 9.22 | 199.34 | 56.66 | 56.66 | 0.143 | 2.86 | |

| PMGw15H | 35 | 57 | 73.8 | 8.93 | 13.38 | 299.01 | 122.6 | 122.6 | 0.215 | |||||||||||||||||||||

Our company give priority to high quality and customer fulfillment and for this we follow stringent good quality control measures. We have now in-house testing facilities where our goods are tested on every single aspect at different processing stages. PYG owning to latest technologies, we facilitate our shoppers with custom made manufacturing facility. Welcome to visit our company and factory, there are various items displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to supply you the best service

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

TOP

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu