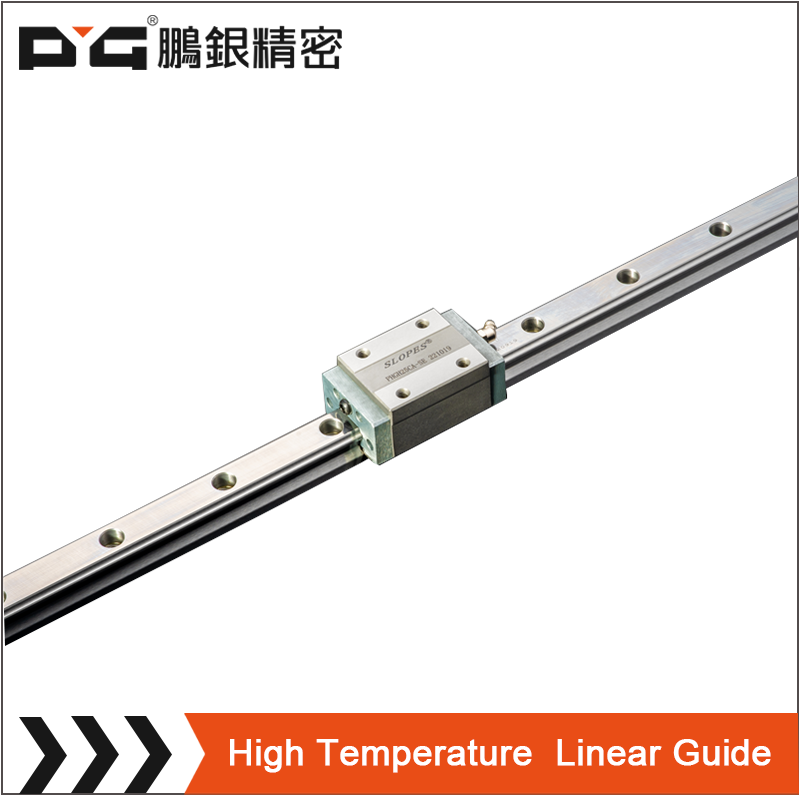

High temperature linear bearings Lm guideways

High Temperature linear Guide

The PYG linear guide can be used in even higher temperatures as a result of using a unique technology for the materials, heat treatment, and the grease can also be used in high temperature environments. Has low rolling resistance fluctuation in response to changes in temperature and a dimension consistency treatment has been applied, which has provided excellent dimensional consistency.

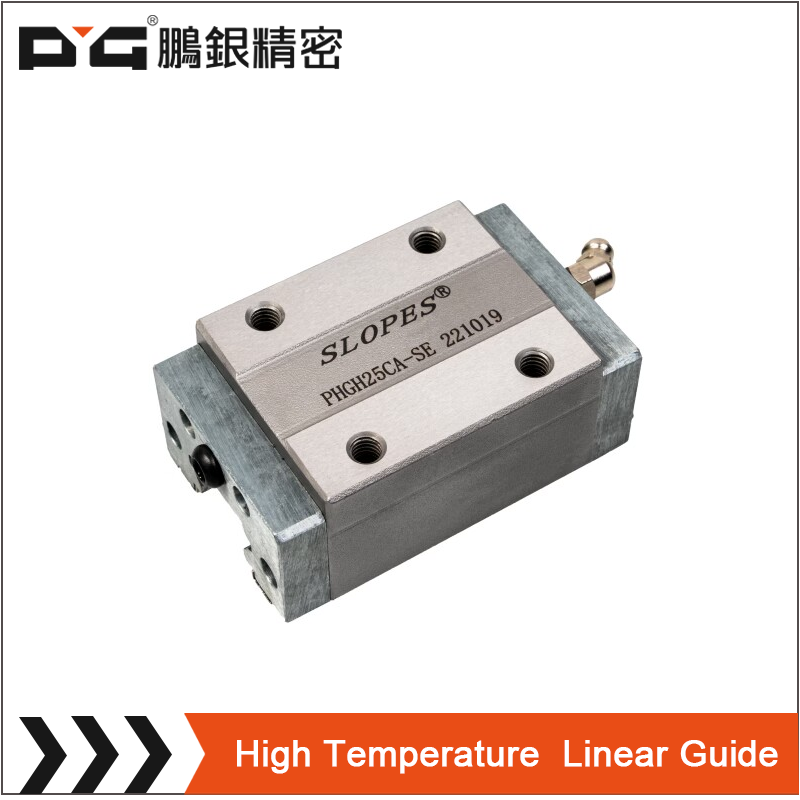

Linear rail carriage feature

High maximum permissible temperature : 150℃

The stainless steel end plate and high-temperature rubber seals allow the guide to be used under high temperature.

High dimensional stability

A special treatment minimizes dimensional fluctuations ( except for thermal expansion at high temperatures)

Corrosion-resistant

The guide is made entirely of stainless steel.

Heat-resistant grease

High temperature grease ( fluorine-based) is sealed in.

Heat-resistant seal

High-temperature rubber used for the seals make them durable in hot environments

Ensuring Superior Performance in Extreme Environments

In today's fast-paced industrial environment, companies are constantly seeking innovative solutions to meet the challenges of extreme temperature changes. We are proud to introduce our newest product - High Temperature Linear Guides - a cutting edge product designed to provide outstanding durability and unmatched performance in high temperature environments.

High-temperature linear guides are designed to perform well in extreme high-temperature conditions, making them ideal for industries with temperatures up to 300°C, such as metalworking, glass manufacturing and automotive production. Manufactured using advanced materials and expert engineering, this product is engineered to withstand the most demanding applications while maintaining its superior functionality.

One of the main features of high temperature linear guides is their robust construction. It is made from a special combination of high-performance materials with excellent thermal stability, ensuring minimal expansion and contraction even under extreme temperature fluctuations. This key attribute ensures consistent and reliable performance, reduces the risk of wear and ultimately extends the life of the guideway.

In addition, the high-temperature linear guides are equipped with an advanced lubrication system, which is carefully designed to withstand extreme high-temperature conditions. This unique lubrication system guarantees smooth and precise linear motion, reduces friction and prevents premature wear. With this capability, operators can expect seamless, reliable operation even in the harshest environments.

Application

Heat treatment equipment

Vacuum enviroment( no vapor dispersion from plastic or rubber)

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

TOP

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu