peb nyob ntawm kab 24 teev kev pabcuam rau koj thiab muab kev sib tham txog kev siv tshuab

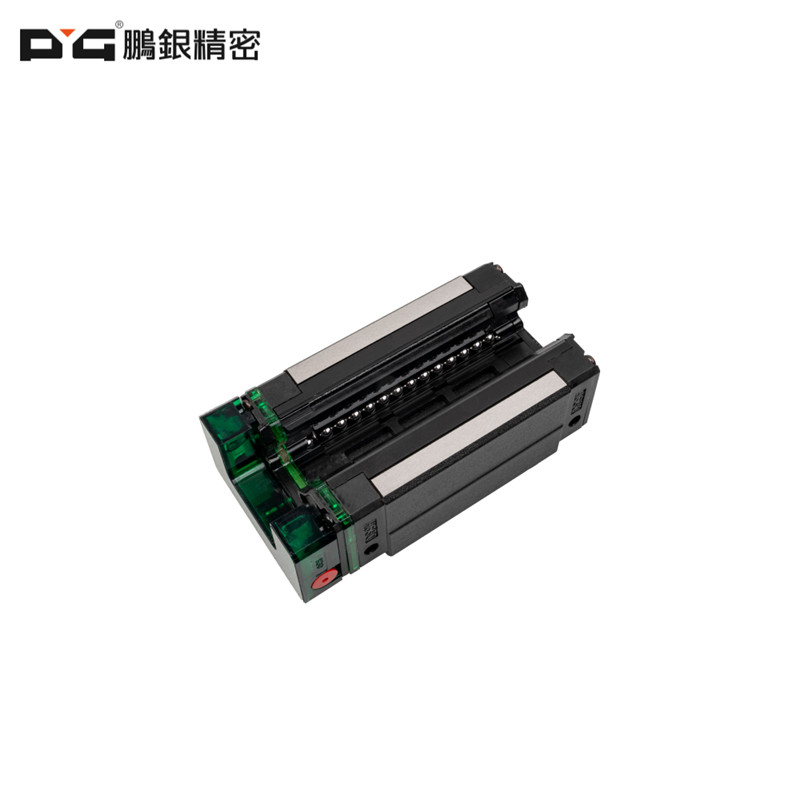

Self lubrication rail thiab carriage swb

E2 series Specification

Ntxiv "/E2" tom qab qhov kev qhia tshwj xeeb ntawm kab ntawv qhia,

Piv txwv li: HGW25CC2R1600ZAPII+ZZ/E2

Qhov ntsuas kub ntawm kev siv

E2 series linear qhia yog haum rau qhov kub ntawm -10 Celsius degree mus rau 60 degrees Celsius.

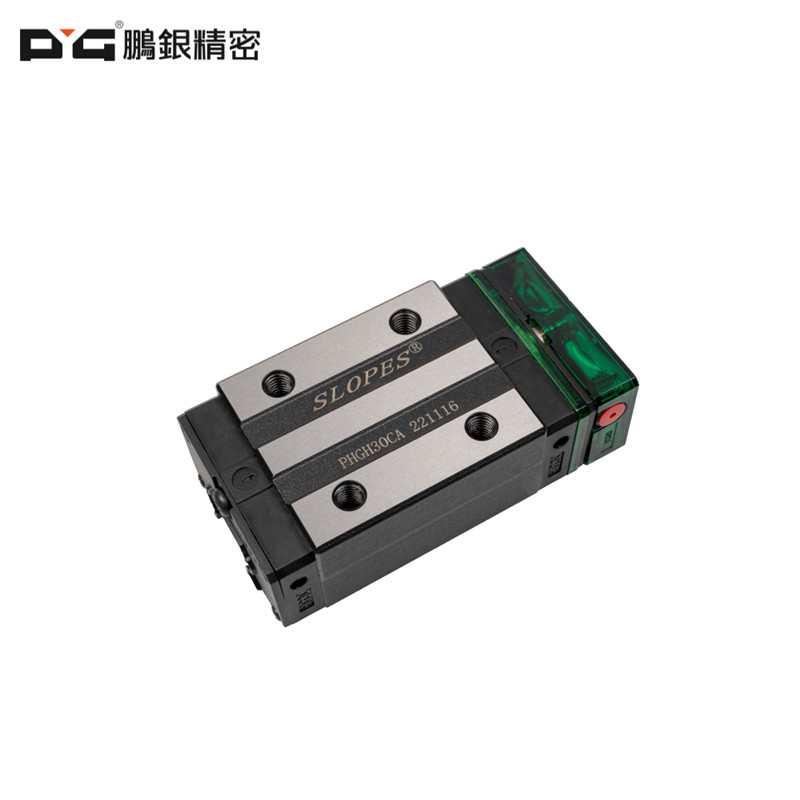

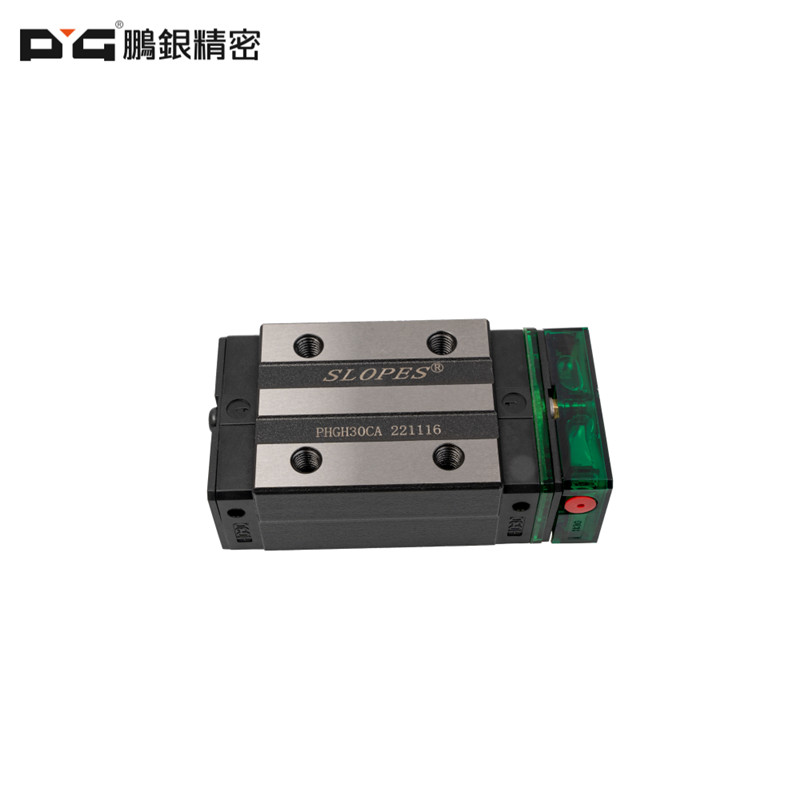

E2 lm rail guide

E2 tus kheej lubrication linear phau ntawv qhia nrog cov qauv lubrication ntawm lub hau thiab cov roj scraper, lub sijhawm no, nrog cov roj tsheb hloov tau rau ntawm qhov kawg ntawm qhov thaiv, saib sab laug:

1) General automation machinery.

2) Kev tsim cov tshuab: yas txhaj tshuaj, luam ntawv, ntawv ua, tshuab textile, tshuab ua zaub mov, tshuab ua haujlwm ntoo thiab lwm yam.

3) Cov tshuab hluav taws xob: cov khoom siv semiconductor, neeg hlau, XY rooj, ntsuas thiab tshuaj xyuas tshuab.

Tus kheej Lubricating Linear Bearings

Kev kuaj xyuas zoo

lubricating linear rails zoo guaranteed, peb khaws txhua tus txheej txheem los ntawm nruj kev xeem.

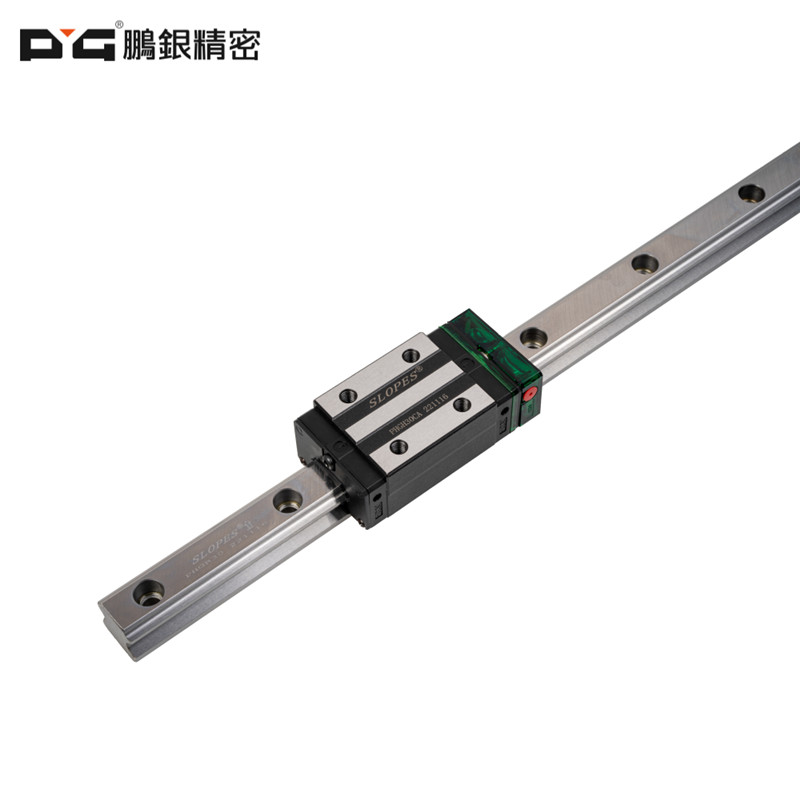

linear motion carriages thiab guide rails

Max ntevntawm linear rail yog 5600mm.Peb tuaj yeem txiav linear rail ntev los ntawm cov neeg siv khoom xav tau (Customized ntev)

Linear zogyog qhov yooj yim tshaj plaws ntawm txhua qhov kev txav.Linear pob bearings muab kev txav mus los hauv ib qho kev taw qhia.Ib tug menyuam bearing, nqa ib tug load los ntawm kev muab dov pob los yog rollers ntawm ob bearing rings hu ua haiv neeg.Cov bearings no muaj ib lub nplhaib sab nraud thiab ob peb kab ntawm cov khoom khaws cia los ntawm tawb.Cov menyuam bearings yog tsim nyob rau hauv ob hom: pob slides thiab cov menyuam swb.

Daim ntawv thov

1. Tsis siv neeg equipments

2. Kev kub ceev hloov khoom siv

3.Precision ntsuas equipments

4.Semiconductor manufacturing khoom

5.Woodworking tshuab.

Nta

1.Kev kub ceev, tsis tshua muaj suab nrov

2.High raug Cov kev sib txhuam tsis tshua muaj txij nkawm

3.Ua-nyob rau hauv lub neej ntev lubrication.

4.International standard dimension.