Hauv kev lag luam automation, cov lus qhia linear ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev sib luag thiab muaj tseeb linear suab.Cov khoom tseem ceeb no yog siv nyob rau hauv ntau yam kev lag luam, los ntawm kev tsim khoom mus rau robotics thiab aerospace. Paub txog cov kev faib ua feem ntawm kev lag luam tawm cov lus qhia yog qhov tseem ceeb rau engineers, designers thiab txhua tus neeg siv koom nrog hauv kev lag luam machinery. Txawm li cas los xij, kuv ntseeg tias qee tus neeg tseem muaj kev tsis ntseeg txog cov kab lus qhia thiab tsis nkag siab txog kev faib tawm ntawm cov lus qhia, yog li hnub no PYG yuav muab cov lus piav qhia ntxaws rau koj.

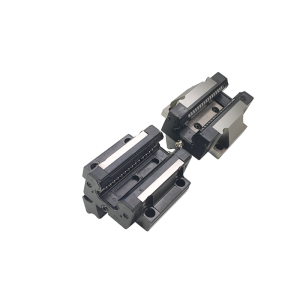

1. Pob bearing linear phau ntawv qhia:

Pob bearing linear qhiayog hom kev siv ntau tshaj plaws vim lawv lub peev xwm thauj khoom siab thiab kev ua haujlwm du. Lawv muaj ob lub ntsiab Cheebtsam: lem thiab carriages. Lub carriage siv recirculating pob bearings uas dov raws rails kom ntseeg tau tias tsis muaj kev sib txhuam. Cov kev taw qhia no zoo tagnrho rau cov ntawv thov uas xav tau siab precision thiab ntev mus ncig, xws li CNC tshuab cuab yeej, laser txiav tshuab, thiab semiconductor manufacturing.

2. Roller linear phau ntawv qhia:

Tsim los rau qhov hnyav dua thiab hnyav ib puag ncig,roller linear qhiasiv cylindrical rollers es tsis txhob pob. Qhov kev teeb tsa no txhim kho lub peev xwm thauj khoom thiab muab kev tiv thaiv zoo dua rau cov kab mob xws li plua plav thiab khib nyiab. Cov menyuam phau ntawv qhia kev tsheb ciav hlau feem ntau yog siv rau hauv kev lag luam machinery xws li hnyav-duty conveyors, khoom siv tuav thiab siv sab nraum zoov.

3. Qhia cov kab ntawv qhia tsuas yog:

Daim ntawv qhia-tsuas yog linear guides, tseem hu ua profile guides, ntiav ib khub ntawm kev taw qhia rails coj kev txav ntawm lub tsheb. Cov qauv tsim no muab siab nruj thiab nruj, ua rau nws tsim nyog rau cov ntawv thov uas xav tau qhov tseeb, rov ua dua, thiab ua haujlwm rau lub zog torsional. Cov lus qhia-tsuas yog cov kab ntawv qhia feem ntau yog siv rau hauv cov cuab yeej siv tshuab, cov neeg hlau ua haujlwm, thiab lwm cov tshuab ua haujlwm siab.

4. Non-guided linear guide rail:

Guideless linear guides cia siab rau ib qho kev tsheb ciav hlau uas tuaj yeem ua raws li radial thiab lateral loads. Nws txoj kev tsim qauv yooj yim tab sis ruaj khov ua rau nws sib haum nrog ntau yam kev siv hauv kev lag luam, suav nrog cov tshuab ntim khoom, tshuab luam ntawv thiab khoom siv kho mob. Ua tsaug rau nws qhov yooj yim, cov lus qhia tsis muaj kab ntawv tuaj yeem hloov kho tau yooj yim rau cov kev taw qhia sib txawv.

Industrial linear guides yog lub hauv paus rau ntau yam kev siv thev naus laus zis niaj hnub no kom ua tiav kev sib tw, muaj tseeb linear suab hauv ntau yam kev lag luam.Los ntawm kev paub txog cov kev faib tawm ntawm cov lus qhia no, cov kws tshaj lij tuaj yeem xaiv hom tsim nyog rau lawv cov kev xav tau tshwj xeeb ntawm daim ntawv thov. Txawm hais tias nws yog rau high-precision pob bearing cov lus qhia lossis rau cov lus qhia hnyav rau cov menyuam, txhua qhov kev faib tawm muaj nws qhov tshwj xeeb zoo. Ua kom muaj kev vam meej kev lag luam automation pib nrog kev xaiv txoj cai linear qhia uas tuaj yeem cuam tshuam rau tag nrho cov kev ua tau zoo, kev ua tau zoo thiab lub neej ntawm cov tshuab. Yog tias koj tsis nkag siab qhov kev piav qhia no, thov tiv taujpeb cov neeg siv khoom, kev pabcuam cov neeg siv khoom yuav ua cov lus piav qhia ntxaws rau koj.

Post lub sij hawm: Aug-11-2023