Serje PHGW lineari slide gwida xaft ferrovija

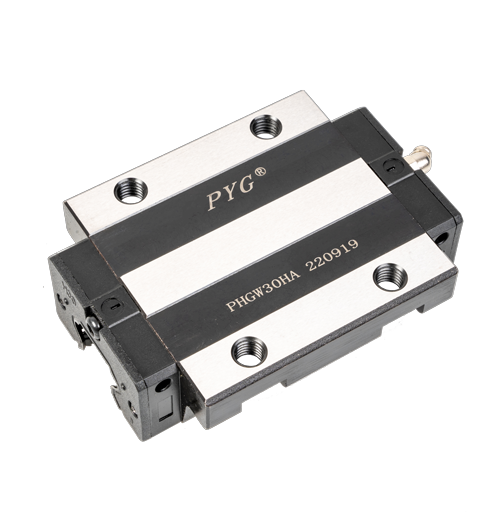

Definizzjoni tal-Ferrovija Lineari tal-Azzar PHGW

PHGW ballun tond lineari gwida bil-ferrovija - blalen tagħbija tqila ħanek tip gwida lineari li huwa żarmar u assemblaġġ faċli, il-wiċċ slide flanġ għandu trattament antisadid ossidazzjoni, operazzjoni stabbli u affidabbli.Dan il-bering lineari tal-flanġ kwadru jadotta materja prima eħxen b'riġidità għolja u ħajja twila ta 'servizz.

Linear Bearing Slide Rails

Ħafna daqsijiet ta 'bearings lineari mill-mudell 15 ~ 65, disinn gotiku ta' erba 'punti ta' kuntatt huwa adottat, ġibda u timbotta bla xkiel, jiżżerżqu stabbli, tul tal-ferrovija tal-gwida lineari tal-bearing jista 'jiġi personalizzat, l-itwal tul jista' jilħaq 6 metri.Blokk tal-bearings lineari juża blalen tal-azzar ta 'preċiżjoni għolja u ebusija għolja, frizzjoni baxxa, storbju baxx u reżistenza baxxa.

lm Blokk Gwida

gwida lm użata ħafna fil-makkinarju tal-kostruzzjoni, inġinerija aerospazjali u strumenti ta 'preċiżjoni eċċ., Meta mqabbla ma' tipi oħra simili ta 'gwidi lineari, PYG®moviment lineari bla xkiel tad-ditta għandu aktar preċiżjoni u karatteristika ta 'kwalità aħjar.

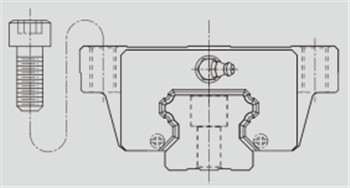

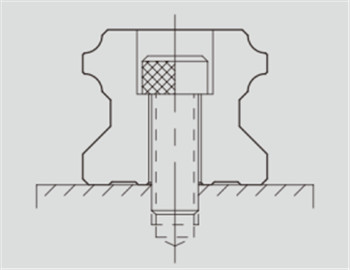

Għas-serje PHGW-CA / PHGW-HA, nistgħu nkunu nafu d-definizzjoni ta 'kull kodiċi kif ġej:

Ħu daqs 30 per eżempju:

Blokk PHGW-CA/PHGW-HA u tip ta 'ferrovija

| Mudell | Dimensjonijiet tal-Assembla (mm) | Dimensjonijiet tal-Blokk (mm) | Dimensjonijiet tal-Ferrovija (mm) | Daqs tal-bolt tal-immuntar għall-ferrovija | Klassifikazzjoni bażika tat-tagħbija dinamika | Klassifikazzjoni bażika tat-tagħbija statika | Moment ratat statiku permissibbli | piż | ||||||||||||||||||||||

| MR | MP | MY | Blokk | Ferrovija | ||||||||||||||||||||||||||

| H | H1 | N | W | B | B1 | C | L1 | L | G | M | T | T1 | H2 | H3 | WR | HR | D | h | d | P | E | mm | C (kN) | C0(kN) | kN-m | kN-m | kN-m | kg | Kg/m | |

| PHGW15CA | 24 | 4.3 | 16 | 47 | 38 | 4.5 | 30 | 39.4 | 61.4 | 5.3 | M5 | 6 | 8.9 | 4.5 | 5.5 | 15 | 15 | 7.5 | 5.3 | 4.5 | 60 | 20 | M4 * 16 | 11.38 | 16.97 | 0.12 | 0.1 | 0.1 | 0.17 | 1.45 |

| PHGW20CA | 30 | 4.6 | 21.5 | 63 | 53 | 5 | 40 | 50.5 | 77.5 | 12 | M6 | 8 | 10 | 6 | 7 | 20 | 17.5 | 9.5 | 8.5 | 6 | 60 | 20 | M5 * 16 | 17.75 | 27.76 | 0.27 | 0.2 | 0.2 | 0.4 | 2.21 |

| PHGW20HA | 65.2 | 92.2 | 21.18 | 35.9 | 0.35 | 0.35 | 0.35 | 0.52 | ||||||||||||||||||||||

| PHGW25CA | 36 | 5.5 | 23.5 | 70 | 57 | 6.5 | 45 | 58 | 84 | 12 | M8 | 8 | 14 | 6 | 9 | 23 | 22 | 11 | 9 | 7 | 60 | 20 | M6 * 20 | 26.48 | 36.49 | 0.42 | 0.33 | 0.59 | 3.21 | |

| PHGW25HA | 78.6 | 104.6 | 32.75 | 49.44 | 0.56 | 0.57 | 0.57 | 0.8 | ||||||||||||||||||||||

| PHGW30CA | 42 | 6 | 31 | 90 | 72 | 9 | 52 | 70 | 97.4 | 12 | M10 | 8.5 | 16 | 6.5 | 10.8 | 28 | 26 | 14 | 12 | 9 | 80 | 20 | M8 * 25 | 38.74 | 52.19 | 0.66 | 0.53 | 0.53 | 1.09 | 4.47 |

| PHGW30HA | 93 | 120.4 | 47.27 | 69.16 | 0.88 | 0.92 | 0.92 | 1.44 | ||||||||||||||||||||||

| PHGW35CA | 48 | 7.5 | 33 | 100 | 82 | 9 | 62 | 80 | 112.4 | 12 | M10 | 10.1 | 18 | 9 | 12.6 | 34 | 29 | 14 | 12 | 9 | 80 | 20 | M8 * 25 | 49.52 | 69.16 | 1.16 | 0.81 | 0.81 | 1.56 | 6.3 |

| PHGW35HA | 105.8 | 138.2 | 60.21 | 91.63 | 1.54 | 1.4 | 1.4 | 2.06 | ||||||||||||||||||||||

| PHGW45CA | 60 | 9.5 | 37.5 | 120 | 100 | 10 | 80 | 97 | 139.4 | 12.9 | M12 | 15.1 | 22 | 8.5 | 20.5 | 45 | 38 | 20 | 17 | 14 | 105 | 22.5 | M12 * 35 | 77.57 | 102.71 | 1.98 | 1.55 | 1.55 | 2.79 | 10.41 |

| PHGW45HA | 128.8 | 171.2 | 94.54 | 136.46 | 2.63 | 2.68 | 2.68 | 3.69 | ||||||||||||||||||||||

| PHGW55CA | 70 | 13 | 43.5 | 140 | 116 | 12 | 95 | 117.7 | 166.7 | 12.9 | M14 | 17.5 | 26.5 | 12 | 19 | 53 | 44 | 23 | 20 | 16 | 120 | 30 | M14 * 45 | 114.44 | 148.33 | 2.69 | 2.64 | 2.64 | 4.52 | 15.08 |

| PHGW55HA | 155.8 | 204.8 | 139.35 | 196.2 | 4.88 | 4.57 | 4.57 | 5.96 | ||||||||||||||||||||||

| PHGW65CA | 90 | 15 | 53.5 | 170 | 142 | 14 | 110 | 144.2 | 200.2 | 12.9 | M16 | 25 | 37.5 | 15 | 15 | 63 | 53 | 26 | 22 | 18 | 150 | 35 | M16 * 50 | 163.63 | 215.33 | 6.65 | 4.27 | 4.27 | 9.17 | 21.18 |

| PHGW65HA | 203.6 | 259.6 | 208.36 | 303.13 | 9.38 | 7.38 | 7.38 | 12.89 | ||||||||||||||||||||||