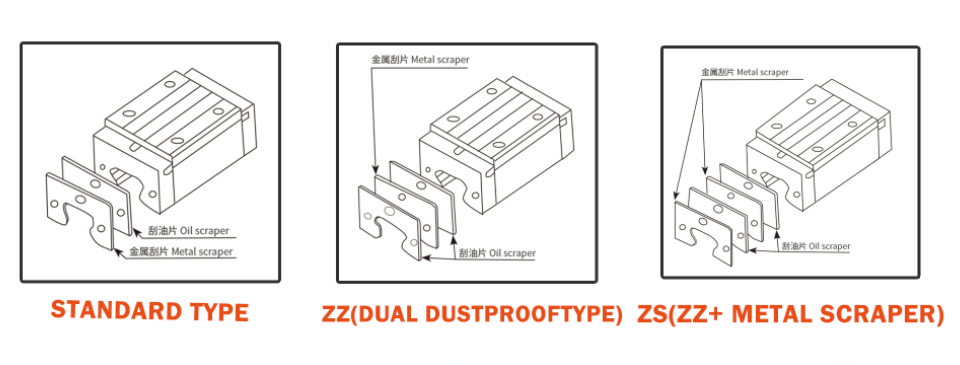

There are three types of dust prevention for PYG sliders, namely standard type, ZZ type, and ZS type. Let's introduce their differences below

Generaly, the standard type is used in a working environment with no special requirement, if there is a special dustproof requirement, please add the code (ZZ or ZS) after the product model.

The“ZZ and ZS”is more suitable for environments with large contaminants ormetal chips, such as milling machines,woodworking machine... etc.

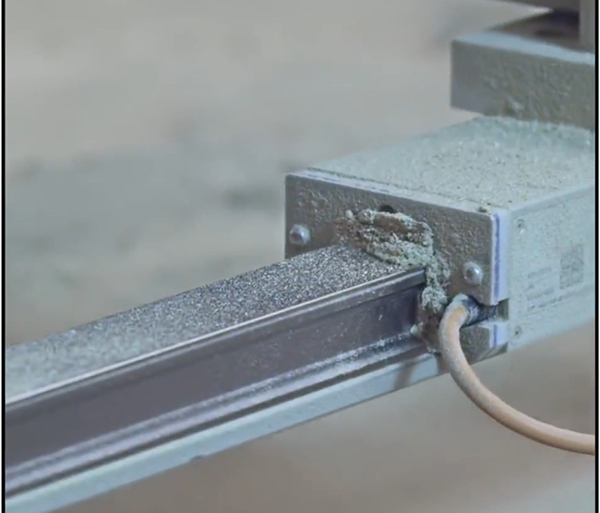

For example, in high dust environments such as cement processing, it is necessary to use ZZ or ZS mode because the machinery needs to be used in dusty environments. Due to the use of multi-layer sealed end caps and sealing film in PYG's high dust slider to prevent dust and debris from entering the slider cavity, it can also prevent lubricant leakage and greatly extend the service life of linear guides in harsh environments.

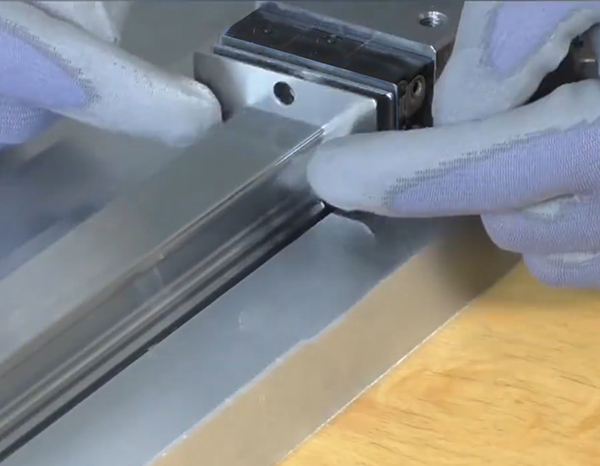

The particles of dust are extremely small and can be said to be ubiquitous. By adding multiple layers of dust-proof scrapers with sliding blocks, these dust particles will not enter the internal ball and roller motion system. This type of scraper can also scrape off the accumulation of dust on the guide rail, greatly reducing the wear and tear on the contact surface. It can also ensure the stable operation of the system in extreme working conditions.

Post time: Nov-28-2024