Linear guides, as an important transmission device, have been widely used in automation equipment. Linear guide is a device that can achieve linear motion, with advantages such as high precision, high stiffness, and low friction, making it widely used in the field of automation equipment.

1. Linear guides have high precision and stability, making them an indispensable part of automation equipment

Linear guides can achieve high-precision linear motion, ensuring that the equipment can be accurately positioned, moved, and processed during operation. This is crucial for some automation equipment that requires extremely high precision, such as CNC machine tools, automatic assembly lines, etc.

2. Linear guides have high rigidity and durability

Linear guides can withstand large loads and inertial forces, ensuring the stable operation of the equipment. This high stiffness characteristic enables linear guides to cope with complex and changing working environments, ensuring long-term and high-intensity operation of the equipment.

3. Linear guides have the characteristics of low friction and high efficiency

The rolling contact between the guide rail and the slider reduces frictional resistance, reduces energy loss, and improves the efficiency of the equipment. This low friction characteristic enables the equipment to be more energy-efficient and reduce operating costs.

4. Linear guides have the advantages of modular design and easy maintenance

The structure of linear guides is relatively simple, and modular design makes installation and maintenance more convenient. Once a problem occurs, damaged components can be quickly replaced, reducing maintenance costs and improving equipment reliability and stability.

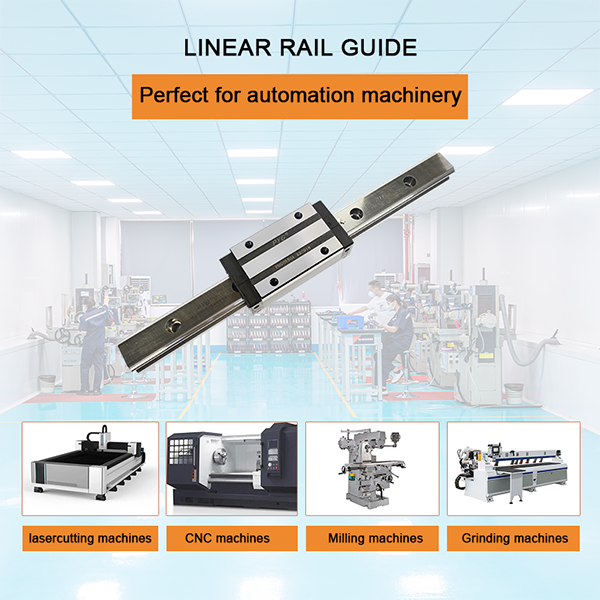

Linear guides are widely used in mechanical equipment, and the following are some common application scenarios:

1. CNC machine tools: Linear guides can provide high-precision and high-speed motion control for CNC machine tools, enabling them to process more precise parts.

2. Automated production line: Linear guides can provide high-precision, high-speed, and high load motion control for automated production lines, enabling them to produce products more efficiently.

3. Printing equipment: Linear guides can provide high-precision and high-speed motion control for printing equipment, enabling the equipment to print more exquisite patterns and text.

4. Electronic devices: Linear guides can provide high-precision and high stability motion control for electronic devices, enabling them to be assembled and tested more accurately.

Post time: Aug-14-2024