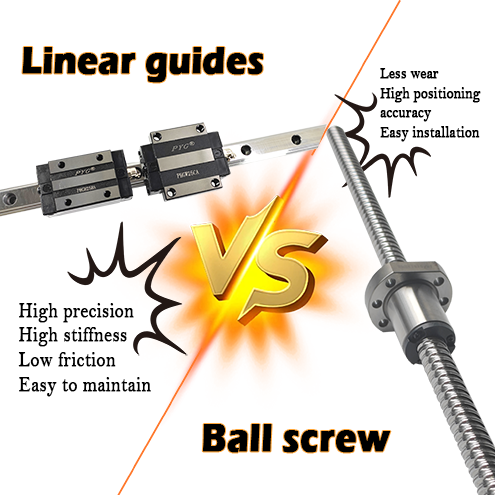

Advantages of linear guides:

1 High precision: Linear guides can provide high-precision motion trajectories, suitable for applications that require high product quality and accuracy, such as semiconductor manufacturing, precision machining, etc.

2. High stiffness: With high stiffness, it can maintain the stability of mechanical systems and withstand large loads and impact forces.

3. High speed: Supports high-speed movement and provides fast positioning capability, suitable for applications that require fast positioning, such as automated production lines, fast packaging machinery, etc.

4. Low friction: Adopting rolling contact method, it has lower friction loss compared to sliding method, improves operating efficiency and reduces energy consumption.

5. Easy to maintain: The structure is simple, and maintenance and upkeep are relatively easy, generally only requiring regular lubrication and cleaning.

6. Long service life: Due to the small frictional force borne by rolling friction, the wire rail is much more ideal than a hard rail in terms of transmission efficiency and service life.

7. Low maintenance cost: As a standard component, the replacement form of the track is similar to replacing a screw, making maintenance convenient.

Advantages of Ball screw:

1 High positioning accuracy: When using linear guides as linear guides, the friction coefficient decreases due to rolling friction, achieving ultra-high precision (um) level positioning accuracy.

2. Less wear: It can maintain accuracy for a long time, and the wear of rolling guidance is very small, so the machine can maintain accuracy for a long time.

3. Easy installation: The installation of the screw is particularly simple, just fix the screw to the fixed frame of the mechanical equipment to complete the installation.

Post time: Nov-21-2024