1. Determine system load: It is necessary to clarify the load situation of the system, including the weight, inertia, direction of motion, and speed of the working object. These pieces of information help determine the required type of guide rail and load-bearing capacity;

2. Determine effective travel: Determine the effective travel of the guide rail based on the position and direction that the machine movement must cover. This involves the range of motion of the work object and the limitations of the workspace;

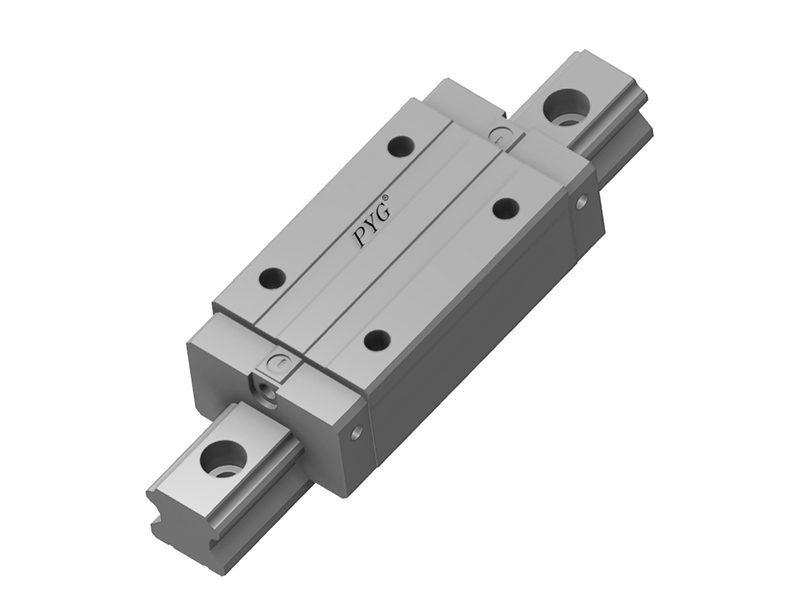

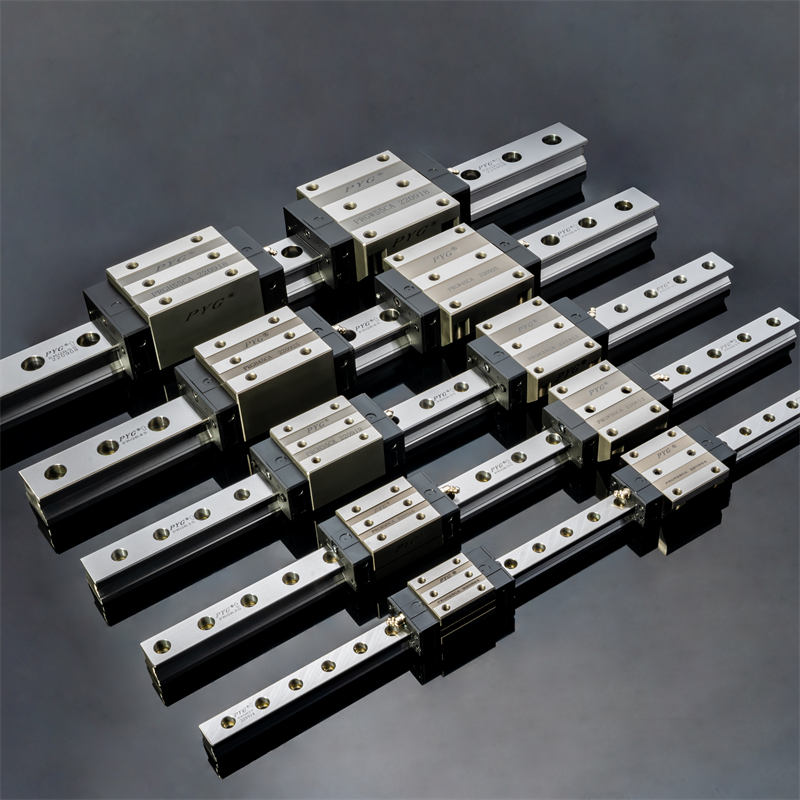

3. Choose the type of guide rail: Based on the application scope and working conditions, choose the suitable linear guide rail type, such as slider type, rolling type, etc. Different types of guide rails have different characteristics and applicable scenarios;

4. Choose guide rail material: The guide rail material needs to have sufficient hardness, wear resistance, and stiffness. Common guide rail materials include steel, aluminum alloy, etc. At the same time, it is necessary to consider whether the hardening treatment on the surface of the guide rail meets the requirements;

5. Determine the accuracy level: Select the appropriate guide rail accuracy level based on work requirements and machining accuracy requirements, including tolerances, sliding friction, and straightness, etc;

6. Determine the number of rails: Calculate and determine the required number of rails based on the required support force and additional load;

7. Consider installation method: Choose a suitable installation method, including horizontal, inclined or vertical installation, as well as brackets, bases or fixed feet, etc;

8. Consider additional requirements: Select relevant accessories according to specific needs, such as guide rail protective covers, dust covers, assembly tools, etc;

9. Consider work environment: Different work environments have different requirements. For example, if the equipment operates in an environment with corrosive gases or liquids, it is necessary to choose corrosion-resistant guide rails; If in a high or low temperature environment, it is necessary to choose a guide rail that can adapt to the environment;

10. Consider maintenance and upkeep: Choose rail designs and materials that are easy to maintain and upkeep to reduce maintenance costs;

11. Considering cost-effectiveness: After considering performance requirements and budget constraints, choose the most economical and practical linear guide rail solution. You can compare guide rails of different brands, materials, and performance to find the most cost-effective linear guide rail.

Post time: Jul-02-2024