Three installation methods are recommended based on the required running accuracy and the degree of impacts andvibrations.

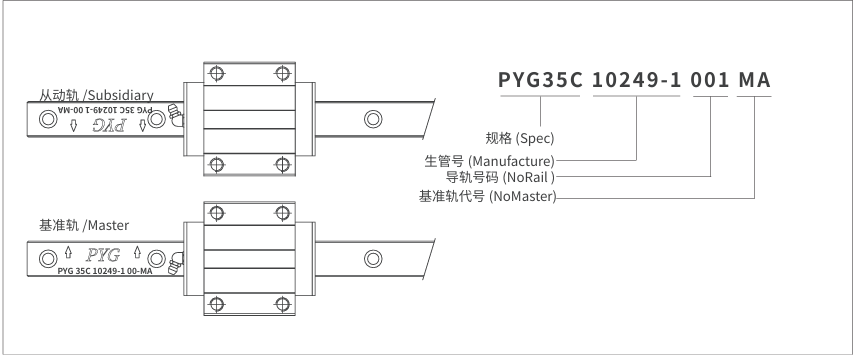

1.Master and Subsidiary Guide

For non-interchangeable type Linear Guides, there are some differences between the master guide and subsidiary guide. The accuracy of the master guide's datum plane is better than the subsidiary's and it can be areference side for installation. There is a mark "MA" printed on the rail, as shown in the figure below.

2.Installation to Achieve High Accuracy and Rigidity

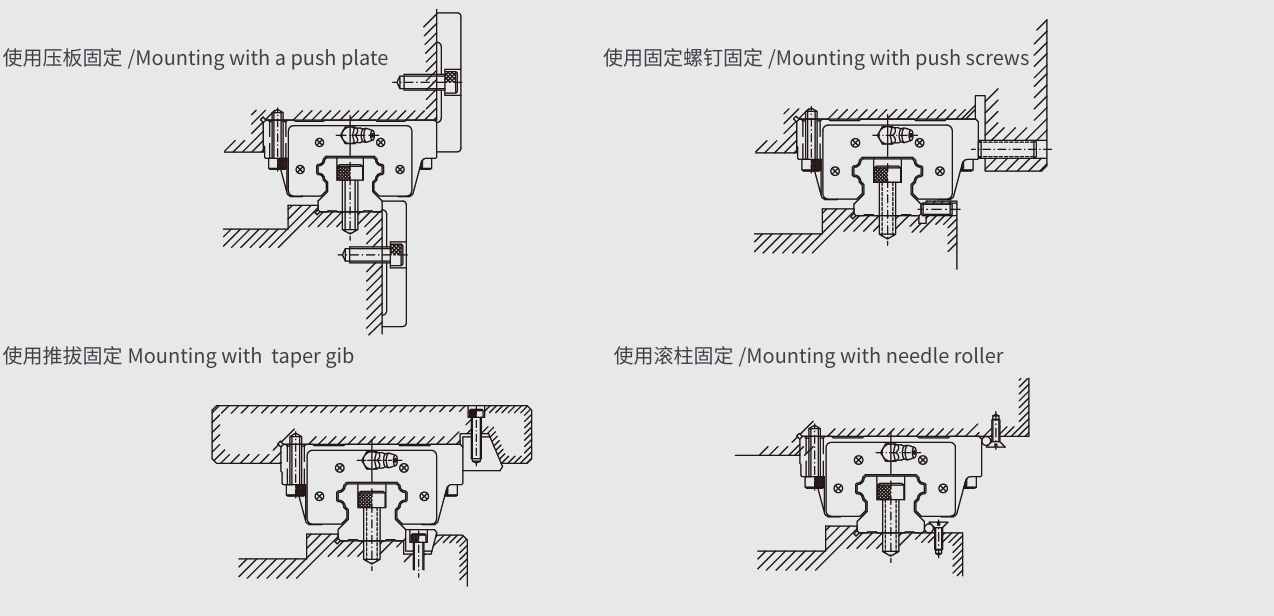

(1) Mounting methods

It is possible that the rails and the blocks will be displaced when the machine is subjected to vibrations and impactsTo eliminate these difficulties and achieve high running accuracy, the following four methods are recommendedfor fixing.

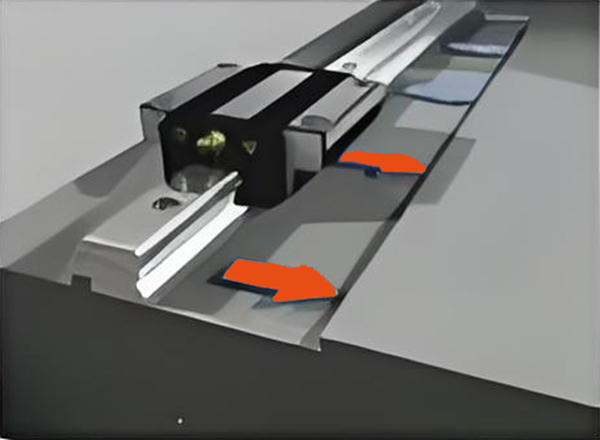

(2) Procedure of linear rail installation

1.Before starting,remove all dirt from the mounting surface of the machine.

2.Place the linear guides gently on the bed Bring the guides into close contact with the datum plane of the bed.

3.Check for correct thread engagement when inserting a bolt into the mounting hole while the railis being placed on the mounting surface of the bed.

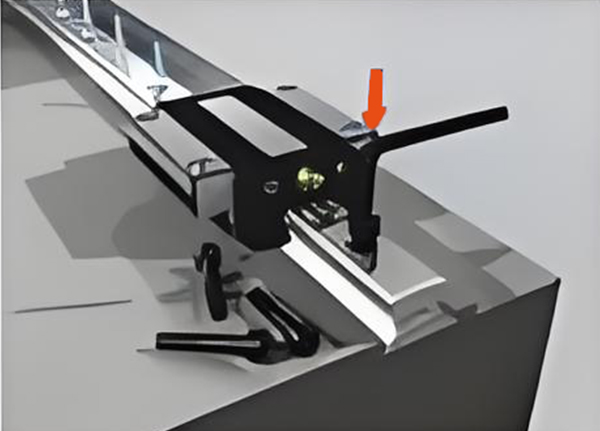

4.Tighten the push screws sequentially to ensure closecontact between the rail and the side datum plane.

5..Tighten the mounting bolts with a torque wrench to the specified torque.

6 .Install theremaining linear guideway in the same way.

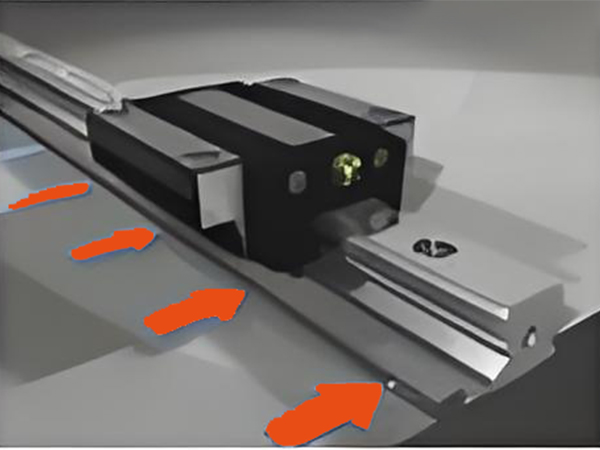

(3) Procedure of block installation

Place the table gently on the blocks. Next, tightenthe block mounting bolts temporarily.

Push the blocks against the datum plane of the table and position the table by tightening the pushs.

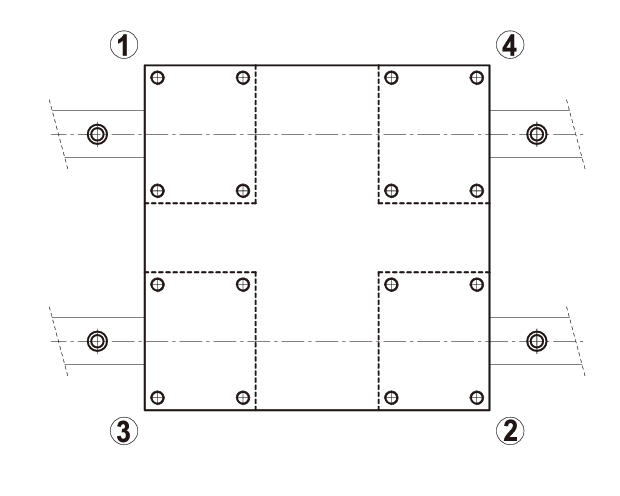

The table can be fixed uniformly by tightening themounting bolts on master guide side and subsidiary side in 1 to 4 sequences.

Post time: Dec-11-2024