In the pursuit of efficiency and precision in industrial manufacturing, the optimization of the performance of linear guides, as key transmission components, directly affects the overall operational effectiveness of the equipment. PYG silent linear guide rail adopts advanced noise reduction technology and precision manufacturing process, which greatly reduces the noise generated by the guide rail during operation.

Through a unique ball circulation system and optimized guide rail structure, the new guide rail effectively reduces friction and collision between the balls and the guide rail, thereby achieving extremely low operating noise. In practical applications, this feature makes the working environment quieter and more comfortable, which helps to improve the concentration and work efficiency of operators.

In addition to its silent feature, PYG linear guides also perform well in terms of smoothness. The manufacturer uses high-quality materials and precision machining technology to ensure that the fit accuracy between the guide rail and the slider reaches the micrometer level. This high-precision coordination makes the slider move more smoothly and smoothly on the guide rail, with almost no lag or impact felt. This smooth motion characteristic is crucial for improving the operational accuracy and stability of equipment, especially in high-precision scenarios such as precision machining and automated production lines.

It is worth mentioning that the silent linear guide also has excellent load capacity and durability. By optimizing the structural design of the guide rail and slider, the contact area and strength of the load-bearing area have been increased, enabling the guide rail to withstand greater radial and axial loads. At the same time, the use of high-quality materials and advanced heat treatment processes has improved the hardness and wear resistance of the guide rail, extending its service life.

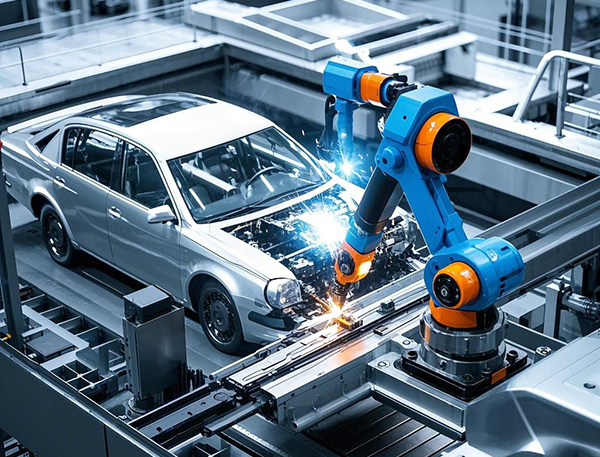

PYG silent linear guide not only meets the market's demand for high-precision and high-efficiency transmission components, but also brings a new solution to the industrial manufacturing field. According to the manufacturer, the product has been successfully applied in multiple industries, including CNC machine tools, electronic manufacturing, automotive assembly, etc. Customer feedback shows that the new guide rail has achieved significant results in improving equipment operating efficiency, reducing noise pollution, and extending equipment service life.

Post time: Mar-19-2025