Supplying insuffcient lubrication to the linear guides will greatly reduce the service life due to an increase in rolling friction. The lubricant provides the following functions;Reduces the rolling friction between the contact surfaces to avoid abrasion andsurface burning of the linear guides; Generates a lubricant fflm between the rolling surfaces and decreases fatique; Anti-corrosion.

1.Grease

Linear guides must be lubricated with the lithium soap based grease before installation. After the linear guides is installed, we recommend that the guides be re-lubricated every 100 km. it is possible to carry out the lubrication through the grease nipple. Generally, grease is applied for speeds that do not exceed 60 m/min faster speeds will require high-viscosity oil as a lubricant.

2.Oil

The recommended viscosity of oil is about 30~150cSt. The standard grease nipple may be replaced by an oil piping joint for oil lubrication. Since oil evaporates quicker than grease, the recommended oil feed rate is approximate 0.3cm³/hr.

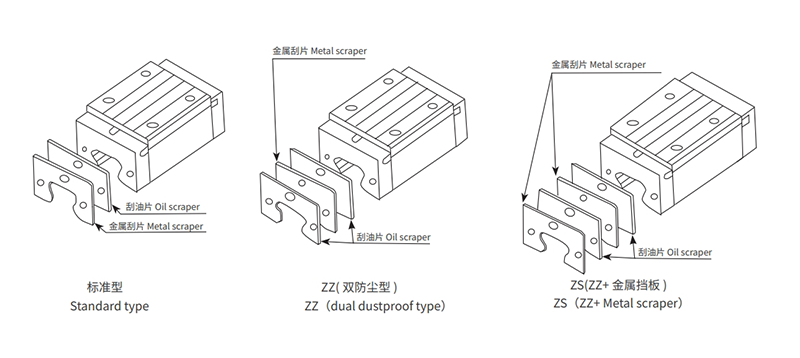

3. Dust Proof

Dustproot: Generally, the standard type is used in a working environment with no special requirement. lf there isa special dustproof requirement, please add the code (ZZ or ZS) after the product model.

Post time: Aug-20-2024