In the linear transmission elements of mechanical equipment, we commonly use ball&roller linear guides. Both are used to guide and support moving parts, but they work in slightly different ways, and understanding how they work can help you choose the right guide for your equipment.

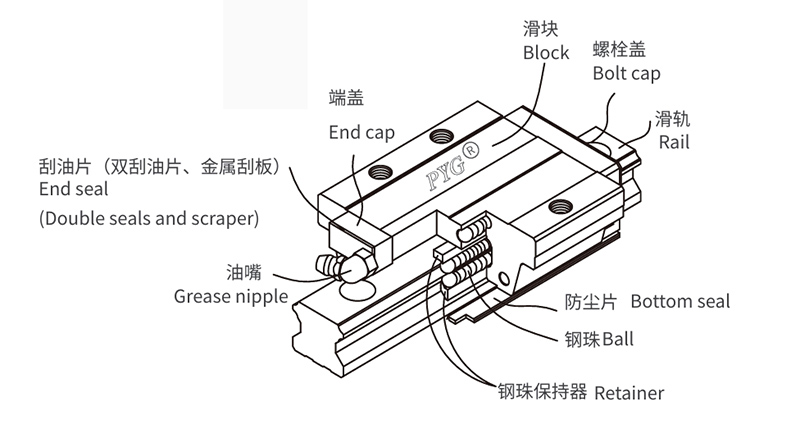

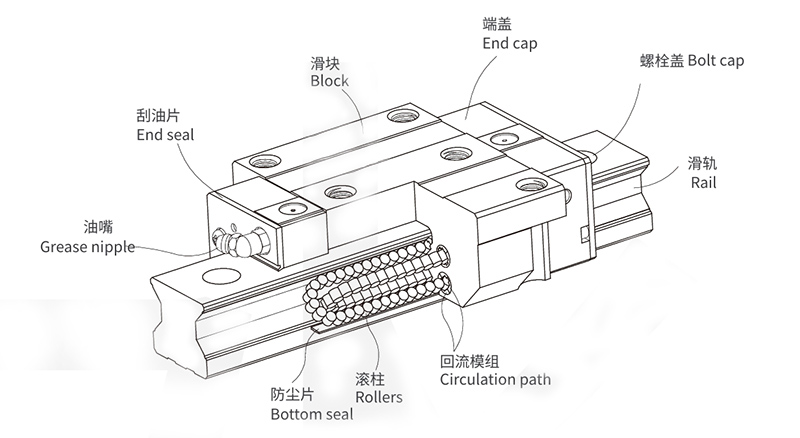

As the name implies, literally, the difference between a ball linear guide and a roller linear guide is the medium in which they roll. The ball linear guide uses rigid balls, and the roller linear guide uses steel columns.

Structure of ball linear guide:

The main difference between ball linear guides and roller linear guides is the bearing capacity.roller guides are similar to ball guides but offer a greater load capacity when compared to the equivalent-size ball version. Due to their compactness and precision, they are often used in large equipment applications.

Structure of roller linear guide:

So, which type of guide is right for your application? The answer depends on a variety of factors, including the load capacity, speed, accuracy and stiffness requirements of the specific application. It is also important to consider environmental factors, such as dust, debris and temperature, as these factors can affect the performance and lifespan of the rails.

The market of PYG is all over the world to provide our clients with factory wholesale linear guides products, Large stock, accept MOQ, fast delivery If you are looking for the fields of precise LM motion system, the PYG team must be your first choice to bring you the right solution.

Post time: Jul-08-2024