Mu makina opanga mafakitale, maupangiri amzere amagwira ntchito yofunikira pakuwonetsetsa kuyenda kosalala komanso kolondola.Zida zofunikazi zimagwiritsidwa ntchito m'mafakitale osiyanasiyana, kuyambira kupanga mpaka ku robotics ndi zakuthambo. Kudziwa magulu odziwika a maupangiri amizere yamafakitale ndikofunikira kwa mainjiniya, opanga ndi aliyense wogwiritsa ntchito makina amakampani. Komabe, ndikukhulupirira kuti anthu ena amakayikirabe za maupangiri amzere ndipo samamvetsetsa kagawidwe ka maupangiri, kotero lero PYG ikupatsirani tsatanetsatane watsatanetsatane.

1. Mpira wokhala ndi mzere wowongolera:

Mpira wokhala ndi zilozera zama mzerendizomwe zimagwiritsidwa ntchito kwambiri chifukwa cha kuchuluka kwa katundu wawo komanso kuyenda kosalala. Amakhala ndi zigawo ziwiri zazikulu: njanji ndi ngolo. Ngoloyi imagwiritsa ntchito ma bere ozungulira a mpira omwe amayenda mozungulira njanji kuti asasunthe. Njira zowongolerazi ndizoyenera kugwiritsa ntchito zomwe zimafunikira kulondola kwambiri komanso kuyenda kwautali, monga zida zamakina a CNC, makina odulira laser, ndi kupanga semiconductor.

2. Wodzigudubuza liniya kalozera:

Zapangidwira katundu wolemera komanso malo ovuta,odzigudubuza liniya akalozeragwiritsani ntchito ma cylindrical rollers m'malo mwa mipira. Kukonzekera uku kumawonjezera kuchuluka kwa katundu ndipo kumapereka kukana bwino kwa zonyansa monga fumbi ndi zinyalala. Njanji zowongolera zodzigudubuza zimagwiritsidwa ntchito kwambiri pamakina akumafakitale monga ma conveyors olemetsa, zida zogwirira ntchito ndi ntchito zakunja.

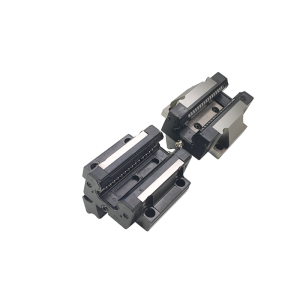

3. Longoletsani mzere wokhawokha:

Maulozera amizere okhawo, omwe amadziwikanso kuti ma profile guides, amagwiritsa ntchito njanji ziwiri zowongolera kayendedwe ka ngolo. Kapangidwe kameneka kamapereka kuuma kwakukulu komanso kusasunthika, ndikupangitsa kuti ikhale yoyenera kugwiritsa ntchito zomwe zimafuna kulondola kwambiri, kubwerezabwereza, komanso kukana mphamvu zama torsional. Maupangiri owongolera okhawo amagwiritsidwa ntchito kwambiri pazida zamakina, maloboti akumafakitale, ndi makina ena olondola kwambiri.

4. Sitima yapanjanji yosatsogolera:

Maupangiri opanda mizera osawongolera amadalira njanji imodzi yomwe imatha kunyamula katundu wozungulira komanso wozungulira. Mapangidwe ake osavuta koma okhalitsa amawapangitsa kuti azigwirizana ndi ntchito zosiyanasiyana zamafakitale, kuphatikiza makina oyikamo, makina osindikizira ndi zida zamankhwala. Chifukwa cha kusinthasintha kwake, chiwongolero chopanda chowongolera chikhoza kusinthidwa mosavuta kumayendedwe osiyanasiyana oyika.

Maupangiri amizere yamafakitale ndiye maziko akupita patsogolo kwaukadaulo wamakono kuti akwaniritse zoyenda zosalala, zolondola m'mafakitale osiyanasiyana.Podziwa magulu odziwika bwino a malangizowa, akatswiri amatha kusankha mtundu woyenera pazofuna zawo zenizeni. Kaya ndi ya owongolera mpira olondola kwambiri kapena owongolera odzigudubuza olemetsa, gulu lililonse lili ndi zabwino zake. Kuwonetsetsa kuti ma automation ochita bwino m'mafakitale kumayamba ndikusankha chiwongolero choyenera chomwe chingakhudze magwiridwe antchito onse, magwiridwe antchito ndi moyo wamakina. Ngati simukumvetsetsa kufotokozeraku, chonde kukhudzanamakasitomala athu, kasitomala adzakufotokozerani mwatsatanetsatane.

Nthawi yotumiza: Aug-11-2023