We have standard quality control process from raw material to finished linear guides, each process is strictly in accordance with international criteria. In PYG, we realize fully automated production line from surface grinding, precision cutting, ultrasonic cleaning, plating, anti-rust oiling to package. We attach importance to solving every practical problem for customers, constantly improve product quality and service.

Raw Material Inspection

1.Check the linear guide and block surface if smooth and flat, there should be no rust, no distortion or no pit.

2.Measure the straightness of rail by feeler gauge and the torsion should be ≤0.15mm.

3.Test the hardness of guide rail by hardness tester, and within HRC60 degree±2 degree.

4.Using the micrometer gauge to test the section dimensions shall not exceed ±0.05mm.

5.Measure the dimension of block by caliper and require ±0.05mm.

Straightness

1.Straight the linear guide by hydraulic press to keep ≤0.15mm.

2.Correct the torsion degree of rail by torque correcting machine within ≤0.1mm.

Punching

1.The hole symmetry should not exceed 0.15mm,the tolerance of through-hole diameter ±0.05mm;

2.The coaxiality of the through hole and the countersunk hole shall not exceed 0.05mm, and orifice inverted angle shall be the same without burrs.

Flat Grinding

1) Put the linear rail on table and held by a disk, flatten with a rubber mallet and grind the bottom of rail,roughness of surface ≤0.005mm.

2) Arrange the sliders on the milling machine platform and finish milling the section surface of sliders. The slider’s angle is controlled ±0.03mm.

Rail & Block Milling

A special grinding machine is used to grind the lanes on both sides of the rail, the width cannot exceed 0.002mm, the center's high standard is +0.02mm, equal height ≤0.006mm, degree of straightness less than 0.02mm, preload is 0.8N, roughness of surface ≤0.005mm.

Finish Cutting

Put the linear slider profile into the finishing cutting machine and cut automatically accurate size of slider, standard of dimension ≤0.15mm, standard of torsion ≤0.10mm.

Inspection

Fixed the linear rail on marble table with screw bolt, and then check the assembly height, straightness and equal height by using standard block and special measuring tool.

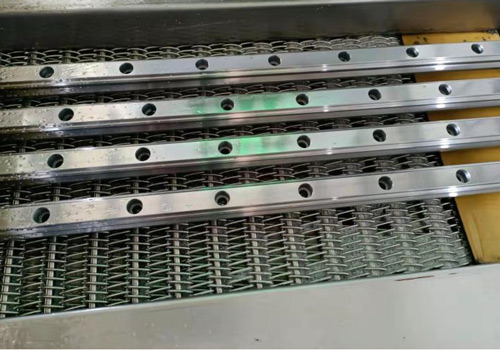

Cleaning

Arrange the guide rail into the inlet raceway of the cleaning machine, keep the spacing into cleaning, demagnetization, drying, spraying rust oil.

Assembly & Package

Keep the surface of linear guide pair no scratch, no rust, no oil in holes, evenly oiling on linear guide surface, the slider runs smoothly without stalling and adhesive tape on package no loose and falls off.