we are on line 24hours service for you and offer professional technology consultation

Self lubricated linear guides

self-lubricating linear guides for improved performance and efficiency

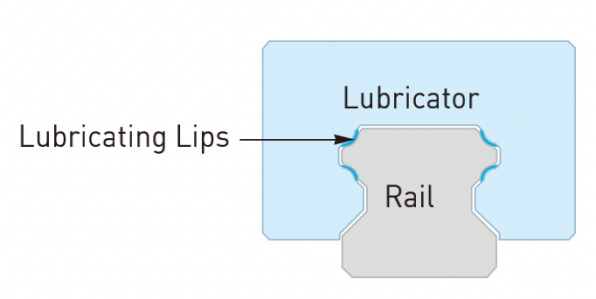

PYG® self-lubricating linear guides are designed to provide superior performance while minimizing maintenance requirements. With built-in lubrication, this advanced linear motion system requires less frequent lubrication, reducing downtime and increasing productivity.

One of the outstanding features of self-lubricating guideways is their unrivaled service life. Thanks to an innovative self-lubricating mechanism, the linear guides distribute lubricant continuously and evenly, ensuring smooth and friction-free motion. This significantly extends the life of the product, reducing the need for constant replacement and costly repairs, ultimately saving time and money in the long run.

In addition to superior durability, self-lubricating linear guides guarantee excellent precision and accuracy. The combination of cutting-edge technology and high-quality materials ensures that vibration and noise are minimized during operation, providing an excellent user experience and increasing the overall efficiency of the machine.

Additionally, self-lubricating linear guides are designed to withstand harsh applications and harsh environments. Its robust construction guarantees its resistance to corrosion, dust and other contaminants, maintaining peak performance even under the most challenging conditions. This exceptional durability minimizes the risk of system failure and maximizes uptime, providing peace of mind and reliability to our customers.

PYG® self-lubricating linear guides are used in a variety of industries including automation, robotics, machine tools, automotive and semiconductor manufacturing, among others. With its versatility and adaptability, this state-of-the-art linear motion system drives innovation and productivity in a variety of applications.

E2 series Specification

- Add “ /E2 ” after the specification of linear guide;

- for example: HGW25CC2R1600ZAPII+ZZ/E2

Temperature range of application

E2 series linear guide is suitable for the temperature from -10 Celsius degree to 60 Celsius degree.

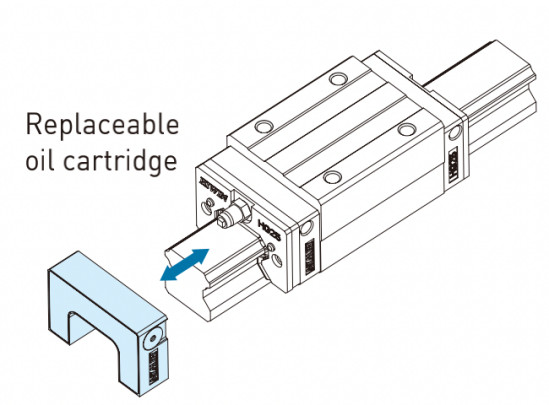

E2 lm rail guide

E2 self lubrication linear guide with the lubrication structure between cap and oil scraper, meanwhile, with replaceable oil carriage on the outer end of block, see left:

Application

1)General automation machinery.

2)Manufacturing machines: plastic injection, printing, paper making, textile machine, food processing machine, wood working machine and so on.

3)Electronic machinery: semiconductor equipment, robotics, X-Y table, measuring and inspecting machine.

Self Lubricating Linear Bearings

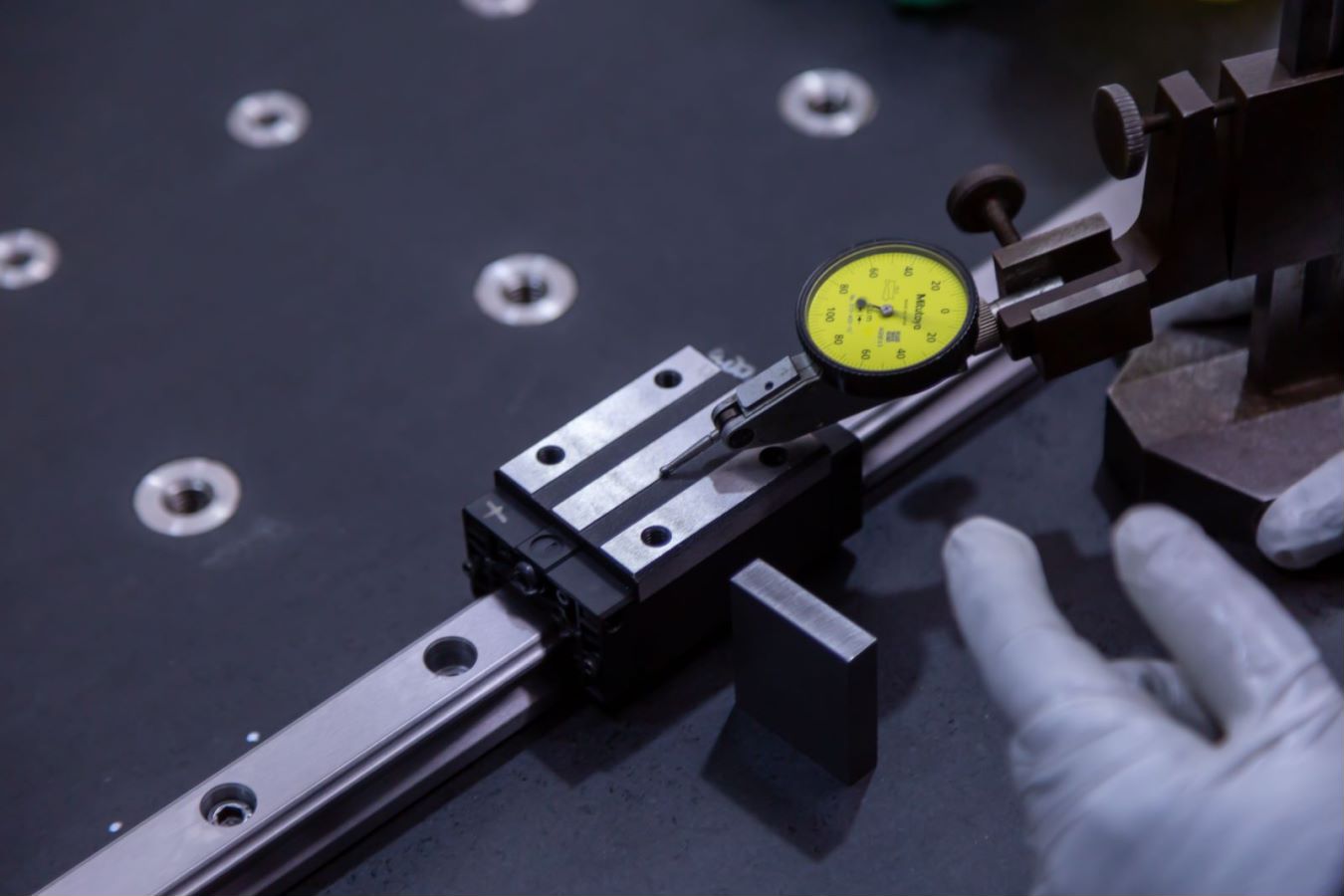

Quality Checking

lubricating linear rails quality ensured, we keep each process through strict professional test.

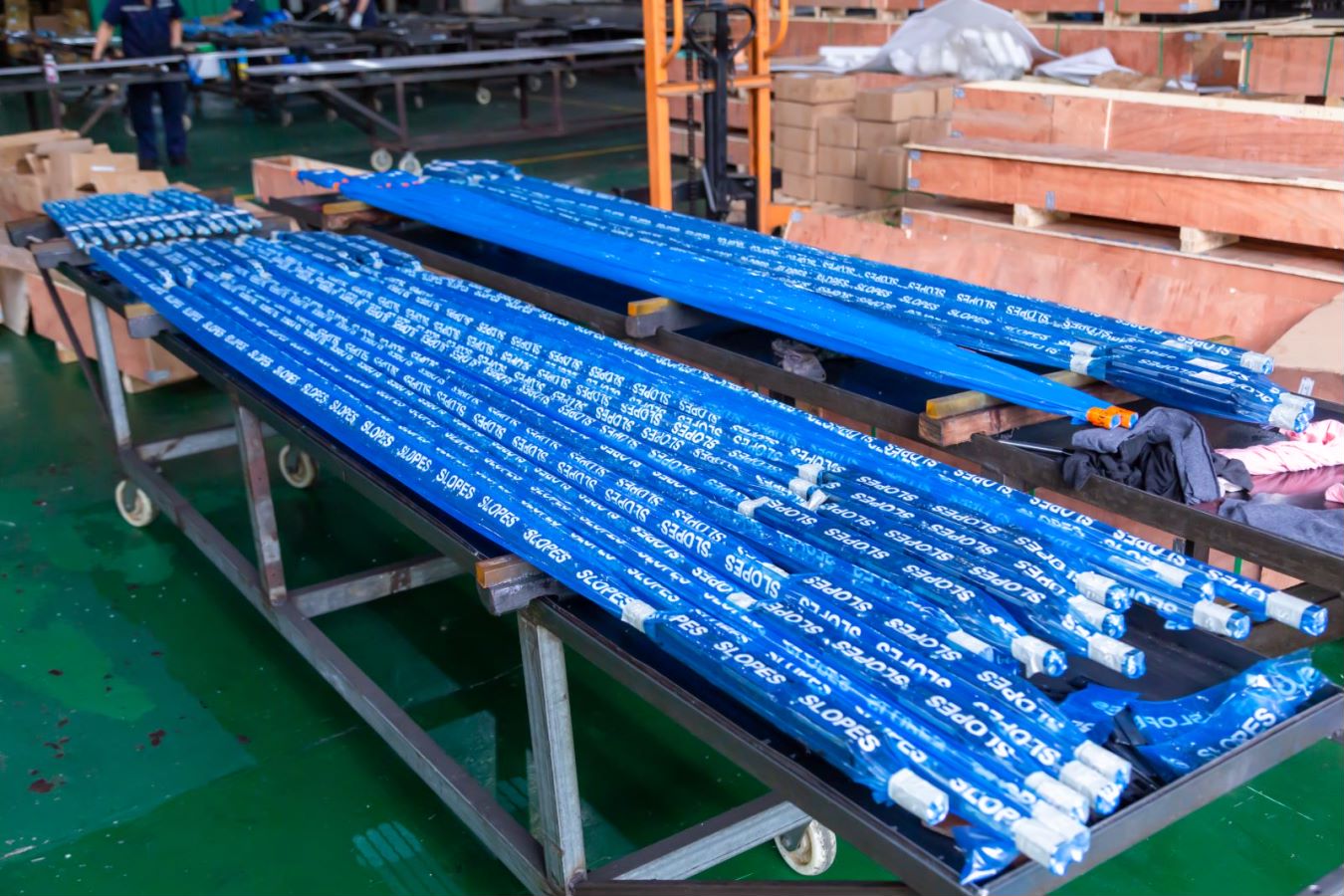

Plastic Package

linear slide system use inner plastic bag , standard export carton or wooden package.

Linear motion carriages and guide rails

Max length of linear rail is available . We can cut linear rail length by customer's requirement (Customized length)

Linear motion is the most basic of all motion. Linear ball bearings provide linear movement in one direction. A roller bearing, carries a load by placing rolling balls or rollers between two bearing rings called races. These bearings are comprised of an outer ring and several rows of balls retained by cages. Roller bearings are manufactured in two styles: ball slides and roller slides.

Application

1.Automatic equipments

2.High speed transfer equipments

3.Precision measuring equipments

4.Semiconductor manufacturing equipment

5.Woodworking machinery.

Features

1.High speed, low noise

2.High accuracy Low friction Low maintenance

3.Built-in long life lubrication.

4.International standard dimension.

Schedule a Consultation Now!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

TOP

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu