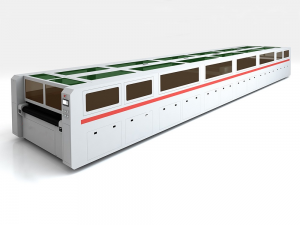

Isticmaalayaal badan oo iibsaday birta mashiinka goynta laser kaliya ayaa fiiro gaar ah u leh dayactirka laser-ka iyo madaxa laser-ka ee fiilada birta laysarka. Dadku waa inay fiiro gaar ah u yeeshaan daryeelka tareenada hagaha.

Waa maxay biraha hagaha toosan

Tilmaamayaal toosanWaxa kale oo loo yaqaan biraha khadka, biraha hagaha toosan, iyo biraha slide toosan. Waxaa loo adeegsadaa codsiyada dhaqdhaqaaqa toosan ee is-waydaarsiga. Waxay leeyihiin culays la qiimeeyay oo ka sarreeya kuwa toosan. Isla mar ahaantaana, waxay xamili karaan torque la hubo waxayna gaari karaan dhaqdhaqaaq toosan oo sax ah oo sarreeya.

Sida biraha toosan u shaqeeyaan

Hagaha toosan waa aaladda gudbinta farsamada oo ka kooban slider iyo atareenada hagaha. Mabda'a shaqadeedu waxay ku salaysan tahay xidhiidhka rogrogashada ee u dhexeeya biraha iyo kubbadaha. Adiga oo isku dubaridinaya xadhkaha kubbada ee jiidhiyaha iyo dejinta dariiqyada orodka ee tareenka hagaha, slideriyuhu waxa uu si toos ah ugu socon karaa xadiidka hagaha.

Inta lagu jiro hawlgalka, thekubadahaIska yaree iska caabbinta isjiidjiidka ah iyadoo la adeegsanayo xiriir rogaal celis ah oo xaqiiji dhaqdhaqaaqa siman ee slider-ka ee tareenka hagaha. Meesha xidhiidhka u dhexeeya kubbadaha iyo jidka orodka waa yar yahay, taas oo yaraynaysa tamarta luminta waxayna hagaajinaysaa waxtarka nidaamka. Hagaha tooska ah ayaa sidoo kale xakameyn kara caabbinta dhaqdhaqaaqa iyo xasilloonida slider-ka iyadoo la hagaajinayo xoogga hore ee culeyska si loo daboolo baahiyaha shaqo ee kala duwan.

Hawlaha mashiinka goynta laysarka hagaha tareenka toosan

Wuxuu ciyaaraa door hanuunin iyo taageero. Si loo hubiyo in mishiinku leeyahay saxnaanta farsamaynta sare, biraha hagaha iyo khadadka toosan ayaa looga baahan yahay inay yeeshaan saxsanaan hagid sare iyo xasillooni dhaqdhaqaaq wanaagsan.

Xadiidka haga waa dammaanadda goynta saxnaanta. Xadiidka hagaha toosan waxa uu ka ciyaaraa door hagitaan iyo taageero ah mishiinka goynta laysarka. Dhaqdhaqaaqa fudud ee xadiidka hagaha, ayaa sare u kaca saxnaanta farsamaynta mashiinka goynta laysarka.

Tayada tareenka hagahawaa dammaanadda nolosha qalabka. Ku rakibida tareenada hagaha iyo hagaajinta mashiinka goynta laysarka waa shay aad muhiim u ah. Ku rakibidda iyo hagaajinta hagaha hagaha mashiinka goynta ayaa gacan ka geysan doona hagaajinta nolosha adeegga iyo goynta saxnaanta mashiinka goynta laysarka.

Si mashiinku u shaqeeyo si caadi ah oo xasilloon, iyo si loo hubiyo tayada processing ee biraha goynta laysarka, dayactirka maalinlaha ah ee xadiidka hagaha iyo dhidibka toosan waa in si taxadar leh loo sameeyaa.

Talaabada 1: Demi awooda Fiber laser cutter

Tallaabada 2: Ka saar birta hagaha toosan oo ku masax wasakh dusha sare ee tareenka hagaha maro engegan.

Tallaabo 3: Marso in yar oo dufan ah jeexdin ee xadiidka hagaha toosan

Talaabada 4: Ku rid dhawr dhibcood oo saliid saliid sayid ah xadiidka hagaha toosan, oo ku celi xadiidka hagaha toosan dhawr jeer si loo hubiyo in saliida saliidayntu ay meel walba taalo xadiidka hagaha.

Tallaabada 5: Ku rakib xadiidka hagaha toosan. Ka dibna shid awoodda ugu weyn ee qalabka goynta laser-ka xaashida oo riix furaha qalabka CNC ee birta.

Waqtiga boostada: Abriil-02-2024