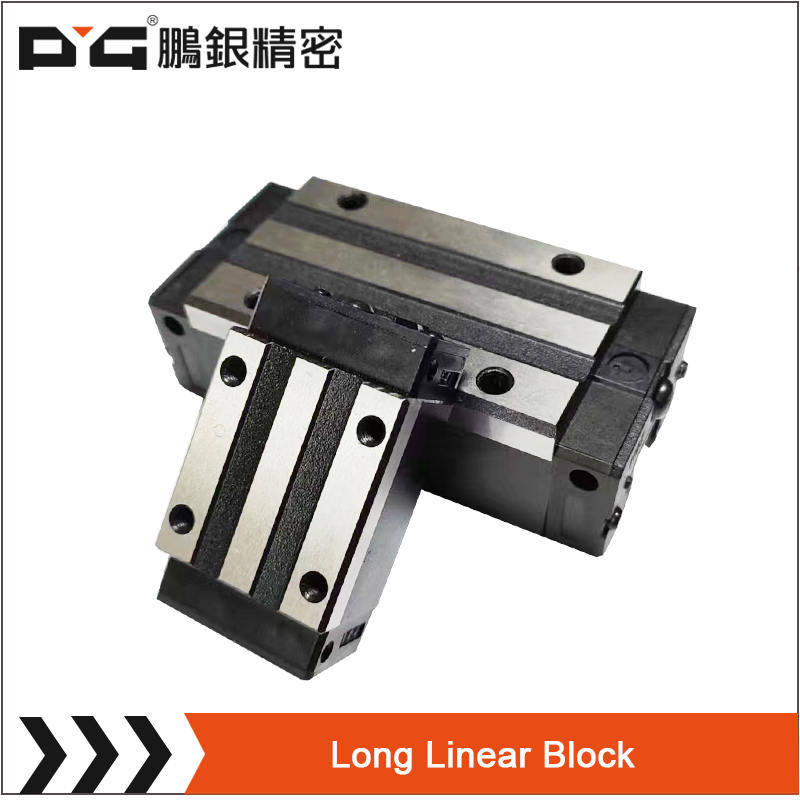

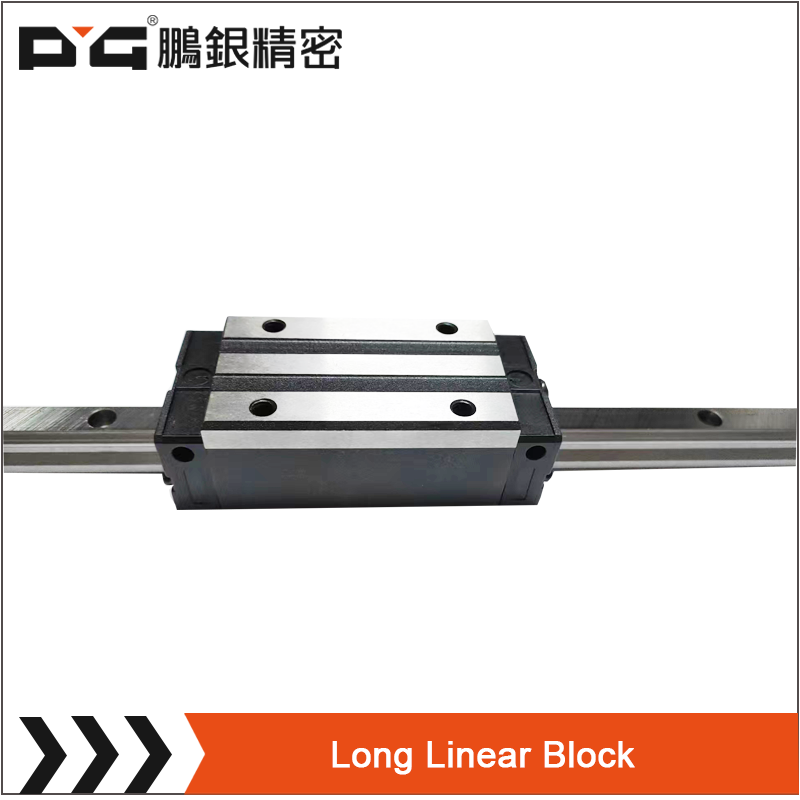

Tsela ea mofuta oa Long Block

Boloko ba tataiso ea mola o molelele

1. Linear guide rail ke e 'ngoe ea likarolo tsa motheo tsa mochine oa mochine oa mochine, o sebelisoang haholo mefuteng e sa tšoaneng ea lisebelisoa tsa mochine oa CNC, litsi tsa machining le lisebelisoa tse ling tse ikemetseng.Ka lebaka la litšoaneleho tsa eona tse tsamaeang hantle, e ka sebelisoa habonolo ho mechine e fapaneng ea ho nepahala le lisebelisoa, tse kang ho hokahanya mechine ea ho lekanya le altimeters, microscopes, joalo-joalo.

2. Ka lebaka la ho nepahala ho phahameng ha motsamao oa linear slider, e sebelisoa haholo ho li-lathes tsa CNC, mechine ea ho sila le lisebelisoa tse ling tse phahameng tsa theknoloji e entsoeng ka thepa ea ho iketsetsa thepa;

3. Ka lebaka la tšebeliso ea tsamaiso ea li-linear motion, e ka ntlafatsa katleho ea tlhahiso le ho fokotsa matla a mosebetsi;

4. Ho itšetlehile ka maemo a mang a khethehileng a ho sebetsa, slider e ka boela ea aroloa ka mofuta o tloaelehileng le mofuta o atolositsoeng.

PHG letoto: Papiso eaboloko ba mola o molelele oa tataisoleboleele bo tlwaelehileng mola wa tataiso boloko

Letoto la PHG: mofuta oa lisekoere le boloko ba tataiso e telele e melang PHGH25HA e nang le PHGR25 linear line

Li-blocks tsa mela e telele li na le moralo o boreleli le o kopaneng o eketsang ts'ebetso e ntle le ho ntlafatsa ts'ebeliso ea sebaka se teng. Ka slider ea eona e telele, e fana ka maeto a malelele, e lumellang sebaka se seholo sa motsamao o sa tsitsang ntle le ho sekisetsa ho nepahala. Moralo ona o mocha o boetse o fokotsa likhohlano le lerata, o netefatsa ts'ebetso e khutsitseng, e se nang likhohlano bakeng sa boiphihlelo bo ntlafalitsoeng ba mosebelisi.

Li-block tsa mela e telele li fana ka ho nepahala le ho nepahala ha motsamao o bonolo le o tsitsitseng. Theknoloji ea eona e tsoetseng pele e tiisa ho khutlela morao ho fokolang le boemo bo nepahetseng bakeng sa taolo e nepahetseng le ho pheta-pheta. Sehlahisoa sena ke tharollo e phethahetseng bakeng sa lits'ebetso tse hlokang motsamao o nepahetseng haholo joalo ka lisebelisoa tsa mochini, liroboto le mela ea kopano e ikemetseng.

Hlokomela:

Haeba o hloka selaete se selelele, ka kopo re bolelle bolelele boo u bo hlokang ha u reka.

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

HLOMPHO

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu