Ho li-automation tsa indasteri, litataiso tsa mela li bapala karolo ea bohlokoa ho netefatsa motsamao o bonolo le o nepahetseng oa mela.Likarolo tsena tsa bohlokoa li sebelisoa liindastering tse fapaneng, ho tloha ho tsa tlhahiso ho isa ho tsa liroboto le tsa sefofane. Ho tseba likarolo tse tloaelehileng tsa litataiso tsa liindasteri ho bohlokoa ho lienjineri, baqapi le mosebelisi e mong le e mong ea amehang mecheng ea indasteri. Leha ho le joalo, ke lumela hore batho ba bang ba ntse ba e-na le lipelaelo ka litataiso tsa linear mme ha ba utloisise karohano ea litataiso, kahoo kajeno PYG e tla u fa tlhaloso e qaqileng.

1. Bukana e tsamaisang bolo:

Litataiso tse tsamaisang boloke mofuta o sebelisoang ka ho fetisisa ka lebaka la matla a bona a phahameng a boima le motsamao o boreleli. Li na le likarolo tse peli tse kholo: lipina le likariki. Koloi e sebelisa li-bearings tsa libolo tse bilikang haufi le liporo ho netefatsa hore ha ho na likhohlano. Litataiso tsena li nepahetse bakeng sa lits'ebetso tse hlokang ho nepahala ho phahameng le maeto a malelele, joalo ka lisebelisoa tsa mochini oa CNC, lisebelisoa tsa laser cutting, le tlhahiso ea semiconductor.

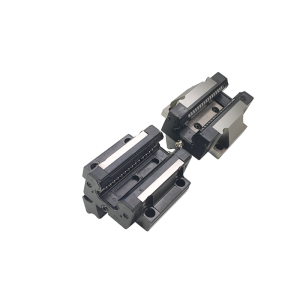

2. Roller linear guide:

E etselitsoe meroalo e boima le maemo a thata,roller linear guidessebelisa li-cylindrical rollers ho e-na le libolo. Tlhophiso ena e ntlafatsa bokhoni ba mojaro mme e fana ka khanyetso e ntle ho litšila tse joalo ka lerōle le lithōle. Lirolara tse tataisang li sebelisoa hangata mecheng ea indasteri joalo ka li-conveyors tse boima, lisebelisoa tsa ho sebetsana le lisebelisoa le lits'ebetso tsa kantle.

3. Tataisa tataiso ea mola feela:

Litataiso tsa litataiso feela, tse tsejoang hape e le litataiso tsa profil, li sebelisa liporo tse tataisang ho tataisa motsamao oa kariki. Moqapi ona o fana ka boima bo phahameng le ho tiea, ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang ho nepahala ho phahameng, ho pheta-pheta, le ho hanyetsa matla a torsional. Litataiso tsa mela e tataisang feela li sebelisoa hangata lithulusing tsa mochini, liroboto tsa indasteri, le lits'ebetso tse ling tse tsamaeang hantle haholo.

4. Seporo sa linear guide se sa tataisoang:

Litataiso tsa mela e se nang tataiso li itšetleha ka seporo se le seng se ka amohelang meroalo ea radial le ea lateral. Moetso oa eona o bonolo empa o tšoarella ka nako e telele o etsa hore e lumellane le mefuta e fapaneng ea lisebelisoa tsa indasteri, ho kenyelletsa le mechini ea ho paka, litsamaiso tsa khatiso le lisebelisoa tsa bongaka. Ka lebaka la ho feto-fetoha ha eona, tataiso e se nang tataiso e ka fetoloa habonolo ho mekhoa e fapaneng ea ho kenya.

Litaelo tsa mehala ea indasteri ke motheo oa likhatelopele tse ngata tsa sejoale-joale tsa theknoloji ho fihlela motsamao o bonolo, o nepahetseng liindastering tse fapaneng.Ka ho tseba lihlopha tse tloaelehileng tsa litataiso tsena, litsebi li ka khetha mofuta o nepahetseng bakeng sa litlhoko tsa bona tse khethehileng tsa kopo. Ebang ke bakeng sa batataisi ba ho beleha bolo ea maemo a holimo kapa bakeng sa batataisi ba lirolara tse boima, sehlopha ka seng se na le melemo ea sona e ikhethang. Ho netefatsa hore othomathike e atlehileng ea indasteri e qala ka ho khetha tataiso e nepahetseng e ka amang ts'ebetso ka kakaretso, katleho le bophelo ba mochini. Haeba u sa utloisise tlhaloso ena, ka kopo tshoanyatšebeletso ea rona ea bareki, tšebeletso ea bareki e tla fana ka tlhaloso e qaqileng bakeng sa hau.

Nako ea poso: Aug-11-2023