Theko e loketseng ea hau ea ho ikhatholla

Ho tseba ho khotsofatsa litlhoko tsa moreki, lits'ebetso tsohle tsa rona li etsoa ka thata moleng ka sepheo sa boleng bo holimo, tlholisano, ts'ebeletso e potlakileng " ho ithuta ho tsoa phihlelong.

Rea u amohela hore u etele thuto ea rona, fektheri le kamore ea rona ea boot e tla fihlela sebaka sa hau sa marang-rang, basebetsi ba rona ba tla leka ho u fa tšebeletso e ntlehali. Haeba u hloka tlhaiso-leseling e ngata, ha ua lokela ho tsilatsila ho ikopanya le rona ka lengolo-tsoibila kapa mohala.

Tlhatlhobo ea E2

- Kenya "/ e2" kamora ho hlalosoa ha tataiso ea mohala;

- Mohlala: HGW25CCC2R1600ZAPII + ZZ / E2

Mocheso oa thepa

Tataiso ea E2 Lisebelisoa tsa Linekhoe e loketse mocheso ho tloha -10 Celsius de Des Decation ho 60 Celsius Stur.

E2 Lm Rail Taolo ea Khoebo

E2 e2

1) Mochine oa Kakaretso oa Automage.

2) Mochini oa tlhahiso: ente ea polasetiki, khatiso, mochini, mochini oa ho sebetsa oa lijo, mochini oa ho sebetsa oa patsi le joalo.

3) Mechine ea elektroniki: Lisebelisoa tsa semiconductor, liroboto, Xy tafoleng, ho lekanya le ho lekola mochini.

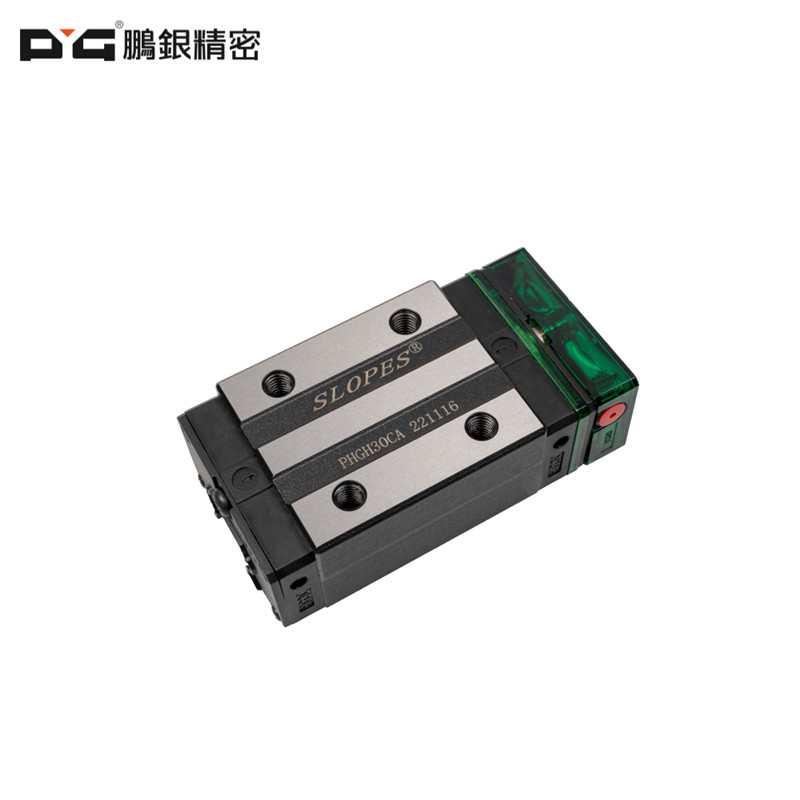

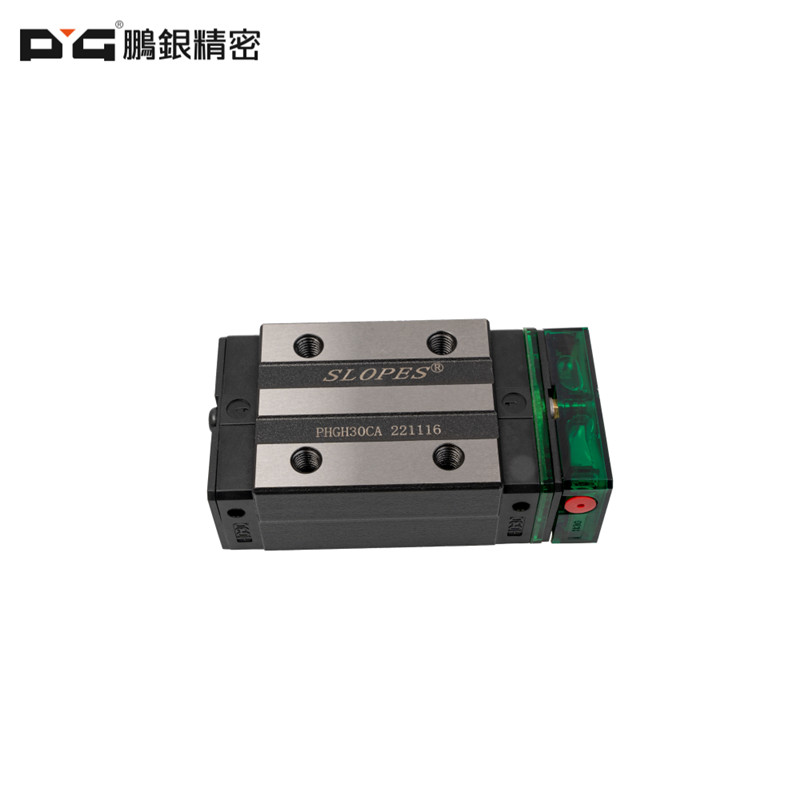

BoithatiLits'oants'o tsa Linear Liaparo

Ho hlahloba boleng

Boqapi ba boleng bo holimo bo ile ba hlaha, re boloka tšebetso e 'ngoe le e' ngoe ka tlhahlobo e thata ea litsebi.

Tekanyo e nepahetseng

Pele ho pakete, LM Tataiso e na le bokhabane bo nepahetseng

Pakete ea polasetiki

Sistimi ea Linear Slide sebelisa sebelisa mokotla oa polasetiki ka hare, Cardina Export Carton kapa sephutheloana sa lehong.

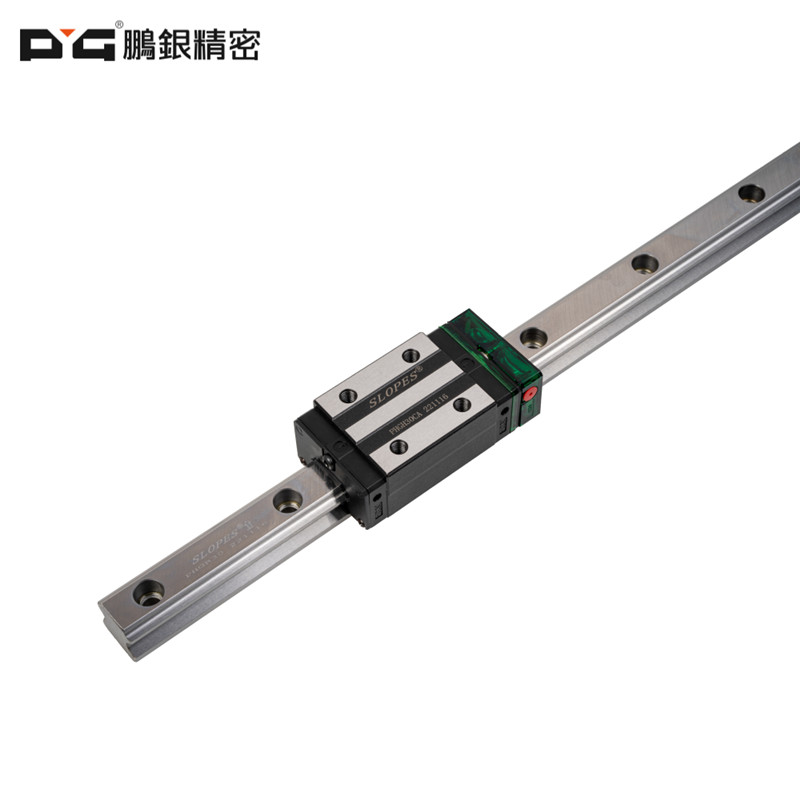

Linear metion le metsamao ea metsamao le li-rails tse tataisang

Bolelele ba Maxea terene ea mela e 5600mm. Re ka fokotsa bolelele ba literene tse nang le tlhoko ea bareki (bolelele bo hlophisitsoeng)

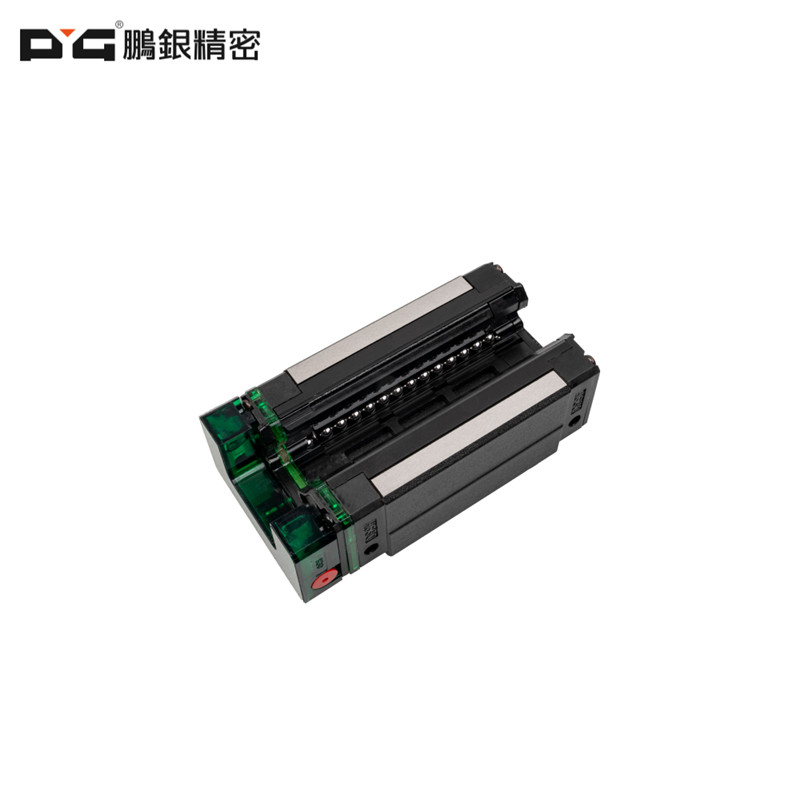

MOSEBETSOke motheo oa ho sisinyeha ho hang. Lijana tsa Mahala tsa Linear li fana ka motsamao oa mohala ka lehlakoreng le leng. Roller e nang le roller, e jara mojaro ka ho beha libolo kapa li-roller tse pakeng tsa mehele tse peli tse bitsoang races. Likarolo tsena li tsamaisoa ka selikalikoe sa kantle le mela e 'maloa ea libolo e bolokiloeng ke likhoele. Lits'oants'o tsa rolar li entsoe ka mekhoa e 'meli ea li-slide: li-slide tsa bolo le li-slide.

Kopo

Lisebelisoa tsa 1.Automatic

2. O itlhomme ka lebelo la ho fetisetsa lebelo

3.PRECING EA METSOALLE EA LITLHAKISO

4.SemiMonductor

5. Mechining ea pele.

Likaroloana

1.Hage lebelo, lerata le tlase

2.Ha Flaigh Friction toitishene e tlase e tlase

3. Pheta - ka bophelo bo bolelele.

Bophahamo bo phahameng bo phahameng bo boholo.

Rala puisano hona joale!

Re le Lipelong tsa 24Holhoang Tšebeletso ea hau le ho fana ka tlhahlobo ea theknoloji ea litsebi

Etsa kopano

Ho tseba ho khotsofatsang litlhoko tsa moreki, lits'ebetso tsohle tsa rona li etsoa ka thata moleng ka sepheo sa rona se phahameng haholo, tlholisano e potlakileng ". Re tla matlafatsa batho ka ho buisana le ho mamela, ho beha mohlala le ba bang le ho ithuta ho tsoa phihlelong.

Rea u amohela hore u etele thuto ea rona, fektheri le kamore ea rona ea boot e tla fihlela sebaka sa hau sa marang-rang, basebetsi ba rona ba tla leka ho u fa tšebeletso e ntlehali. Haeba u hloka tlhaiso-leseling e ngata, ha ua lokela ho tsilatsila ho ikopanya le rona ka lengolo-tsoibila kapa mohala.

Mekhahlelo ea lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

Holimo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur