Abasebenzisi abaninzi abathenge i-laser cutting machine metal banikela ingqalelo kuphela ekugcinweni kwe-laser kunye nentloko ye-laser ye-fiber laser metal cutter. Abantu kufuneka banike ingqwalasela engaphezulu kukhathalelo lwesikhokelo sikaloliwe.

Yintoni na iileyili zesikhokelo somgca

Izikhokelo zomgcazikwabizwa ngokuba ngoololiwe bomgca, iileyili zesikhokelo esinemigca, kunye nemigca yesilayidi. Zisetyenziswa kwizicelo zentshukumo ezihambelanayo. Zinomthwalo ophakamileyo ophezulu kuneebheringi zomgca. Kwangaxeshanye, banokuthwala i-torque eqinisekileyo kwaye banokufezekisa intshukumo ephezulu ye-Precision linear.

Zisebenza njani iireyili zemigca

Isikhokelo somgca sisixhobo sothumelo somatshini esenziwe sisilayidi kunye aumzila kaloliwe. Umgaqo wayo wokusebenza usekelwe kuqhagamshelwano olujikelezayo phakathi kweebheringi kunye neebhola. Ngokucwangcisa iibheringi zebhola ngaphakathi kwesilayidi kunye nokubeka iindlela zomdyarho kumgaqo kaloliwe wesikhokelo, isilayidi sinokuhamba ngomgca ecaleni komgaqo kaloliwe.

Ngexesha lokusebenza, iiibheringi zebholaukunciphisa ukuxhathisa ukukhuhlana ngoqhagamshelwano oluqengqelekayo kunye nokufezekisa intshukumo egudileyo yesilayidi kumzila wesikhokelo. Indawo yoqhagamshelwano phakathi kweebhola kunye ne-raceway encinci, eyanciphisa ukulahlekelwa kwamandla kunye nokuphucula ukusebenza kakuhle kwenkqubo. Isikhokelo somgca sinokulawula ukuchasana kwentshukumo kunye nokuzinza kwesilayidi ngokulungelelanisa amandla okulayisha kwangaphambili ukuhlangabezana neemfuno ezahlukeneyo zomsebenzi.

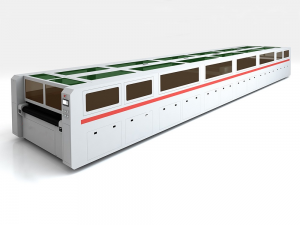

Imisebenzi yomatshini wokusika we-laser umgca wesikhokelo sikaloliwe

Udlala indima yokukhokela kunye nenkxaso. Ukuze kuqinisekiswe ukuba umatshini unokuchaneka okuphezulu kokusebenza, iileyili zesikhokelo kunye nemigca ethe tye kufuneka ibe nokuchaneka okuphezulu kokukhokela kunye nokuzinza okuhle kokuhamba.

Umzila wesikhokelo sisiqinisekiso sokuchaneka kokusika. Umzila wesikhokelo somgca udlala indima ekhokelayo kunye nenkxaso kumatshini wokusika i-laser. Ukuhamba kakuhle komzila wesikhokelo, ukuphakamisa ukuchaneka kokulungiswa komatshini wokusika we-laser.

Umgangatho wesikhokelo sikaloliwesisiqinisekiso sobomi besixhobo. Ukufakwa kukaloliwe wesikhokelo kunye nohlengahlengiso lomatshini wokusika i-laser yinto ebaluleke kakhulu. Ukufakwa kunye nokulungelelaniswa komzila wesikhokelo somatshini wokusika kuya kunceda ukuphucula ubomi benkonzo kunye nokusika ukuchaneka komatshini wokusika i-laser.

Ukwenza umatshini usebenze ngokuqhelekileyo kwaye uzinzile, kunye nokuqinisekisa umgangatho wokucubungula umatshini wensimbi yokusika i-laser, ukugcinwa kwansuku zonke komzila wesikhokelo kunye ne-axis yomgca kufuneka kwenziwe ngokucophelela.

Inyathelo 1: Cima amandla e-fiber laser cutter

Inyathelo lesi-2: Susa umzila kaloliwe wesikhokelo kwaye usule ukungcola kumphezulu wesikhokelo ngelaphu elomileyo.

Inyathelo lesi-3: Faka igrisi encinci kumjelo wesiporo sesikhokelo somgca

Inyathelo lesi-4: Lahla amathontsi ambalwa e-oyile yokuthambisa kumzila kaloliwe wesikhokelo, kwaye ubuyisele umgaqo kaloliwe amatyeli aliqela ukuqinisekisa ukuba ioyile yokuthambisa ikuyo yonke indawo kumgaqo kaloliwe.

Inyathelo lesi-5: Faka umzila kaloliwe wesikhokelo. Emva koko vula amandla aphambili e-sheet metal laser cutting tool kwaye ucinezele ukutshintshela i-CNC laser cutter yesinyithi.

Ixesha lokuposa: Apr-02-2024