1. Izinga lokuqhuba liyancipha kakhulu

Ngenxa yokubaIsilayidi esishukumayo esishukumayo intshukumo yefriction incinci, kufunwa amandla amancinci kuphela, unokwenza intshukumo yomatshini, ifaneleke ngakumbi ukuqala ngesantya esiphezulu kunye nokubuyisela umva intshukumo.

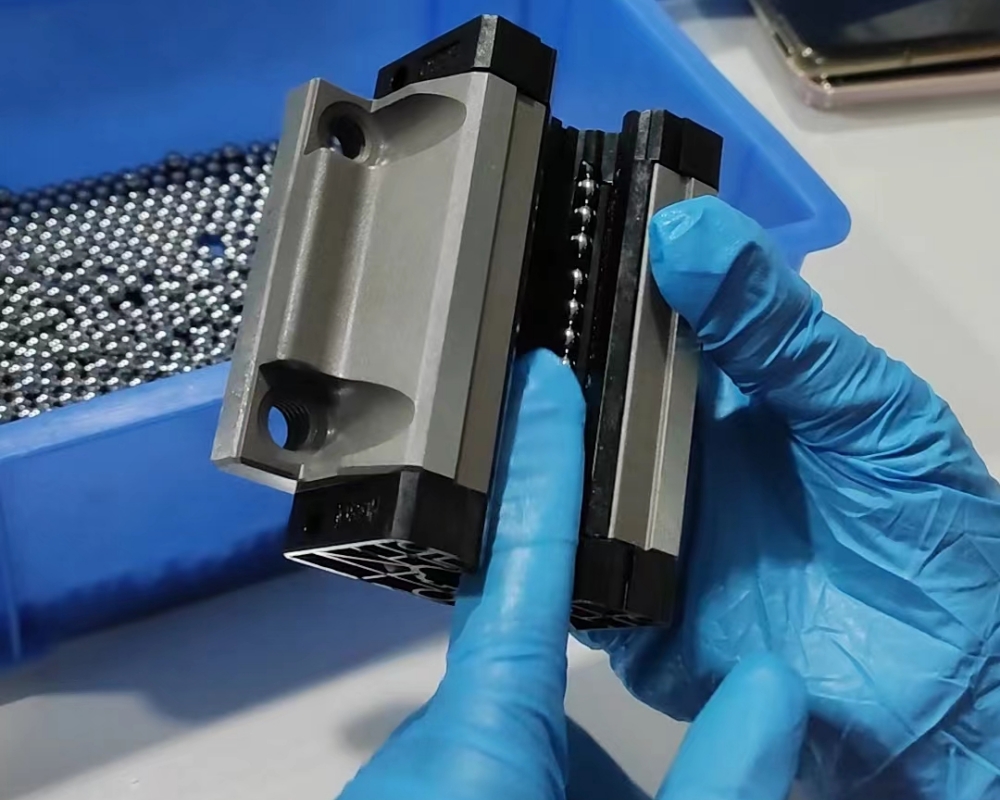

2. Isilayidi sisebenza ngokuchaneka okuphezulu

Intshukumo yeIsilayidi seSikhokelo sikaLoliweibonwa ngokuqengqeleka. Ayisiyiyo kuphela i-coefficient ye-friction iyancitshiswa ukuya kwi-fifti ye-sliding guide rail, ukwenzela ukuba kuphunyezwe ukunyakaza okuzinzile, kodwa nokunciphisa ukutshatyalaliswa kunye nokungcangcazela, okufanelekileyo ekuphuculeni isantya sokuphendula kunye novakalelo lwenkqubo ye-CNC.

3. Isakhiwo esilula sokuthambisa

Umlomo weoyile weibhloko ekhokelwa ngumgca inokufakwa kwisilayidi inokufakwa ngokuthe ngqo kwi-oyile okanye idityaniswe kumbhobho weoyile ukufezekisa unikezelo lweoyile oluzenzekelayo ukuze umatshini unokunciphisa ukunxiba.

4. Ufakelo olulula kunye nokutshintshiselana okuphezulu kwebhloko yesilayidi

Impazamo yokufakela isikrufu somngxuma wesilayidi esinobume obuphezulu sincinci. Emva kokuba ukuchaneka kwamacandelo kuncitshisiwe, umatshini unokutshintshwa ukuze ufezekise ukuchaneka okuphezulu kwakhona

5. Amandla okutywina owomeleleyo

Imizila yesikhokelo somgca inomsebenzi olungileyo wobungqina bothuli. Iziphelo zokutywina zifakwe kuzo zombini iziphelo zeebhloko zesilayidi zeendlela ezininzi zesikhokelo ukuqinisekisa ukusebenza kokutywinwa. Ipleyiti yokutywina ekhethiweyo emazantsi eentsimbi zesilayidi ixhotyiswe ngezigqubuthelo zobungqina bothuli ukunqanda ukufumba kothuli.

Ukuba ufuna ukwazi iinkcukacha ezithe vetshe malunga nezikhokelo zomgca, ncedaQhagamshelana nathingokukhawuleza okukhulu!!!

Ixesha lokuposa: Dec-28-2023