Iziqondiso zomugqa, njengethuluzi lokudlulisela elibalulekile, lisetshenziswe kabanzi kuimishini ezishintshayo. Igayidi yomugqa iyisisetshenziswa esingafinyelela ukunyakaza komugqa, ngezinzuzo ezifana nokunemba okuphezulu, ukuqina okuphezulu, nokungqubuzana okuphansi, okuyenza isetshenziswe kabanzi emkhakheni wezinto ezishintshayo.

1. Iziqondiso ezinomugqa zinokunemba okuphezulu nokuzinza, okuwenza abe yingxenye ebalulekile yemishini ezishintshayo

Imihlahlandlela yomugqa ingafinyelelaukunemba okuphezuluukunyakaza okuqondile, okuqinisekisa ukuthi okokusebenza kungabekwa kahle, kuhanjiswe, futhi kusetshenzwe ngesikhathi sokusebenza. Lokhu kubalulekile kwezinye izinto zokusebenza ezizenzakalelayo ezidinga ukunemba okuphezulu kakhulu, njengamathuluzi omshini we-CNC, imigqa yokuhlanganisa ezenzakalelayo, njll.

2. Iziqondiso ezinomugqa zinokuqina okuphezulu nokuqina

Iziqondiso zomugqa zingamelana nemithwalo emikhulu namandla angenayo, okuqinisekisa ukusebenza okuzinzile kwemishini. Lesi sici sokuqina okuphezulu senza iziqondiso ezilandelanayo zikwazi ukubhekana nezimo zokusebenza eziyinkimbinkimbi nezishintshayo, ziqinisekisa ukusebenza kwesikhathi eside kanye nokuqina okuphezulu kwemishini.

3. Abaqondisi bomugqa banezici zeukungqubuzana okuphansi nokusebenza kahle okuphezulu

Ukuxhumana okugoqekayo phakathi kwesitimela somhlahlandlela nesilayida kunciphisa ukumelana nokungqubuzana, kunciphisa ukulahleka kwamandla, futhi kuthuthukisa ukusebenza kahle kwezisetshenziswa. Lesi sici esiphansi sokungqubuzana senza izinto zokusebenza ziwonge kakhudlwana futhi zinciphise izindleko zokusebenza.

4. Iziqondiso ezinomugqa zinezinzuzo zokuklama kwe-modular kanye nokugcinwa okulula

Isakhiwo semihlahlandlela eqondile silula, futhi ukwakheka kwe-modular kwenza ukufakwa nokugcinwa kube lula. Uma inkinga seyenzekile, izingxenye ezilimele zingashintshwa ngokushesha, kwehliswe izindleko zokuyilungisa futhi kuthuthukiswe ukwethembeka nokuzinza kwemishini.

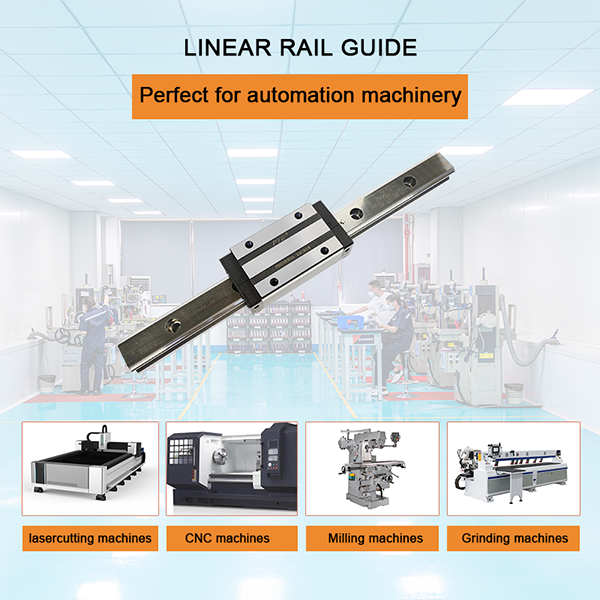

Imihlahlandlela yomugqa isetshenziswa kakhulu kumishini eyimishini, futhi okulandelayo yizimo zohlelo ezijwayelekile:

1. Amathuluzi omshini we-CNC: Iziqondiso ezinomugqa zingahlinzeka ngokunemba okuphezulu nokulawula ukunyakaza kwesivinini esikhulu kumathuluzi omshini we-CNC, okubenza bakwazi ukucubungula izingxenye ezinembe kakhudlwana.

2. Ulayini wokukhiqiza ozenzakalelayo: Imihlahlandlela eqondile inganikeza ukunemba okuphezulu, isivinini esikhulu, nokulawula ukunyakaza komthwalo ophezulu emigqeni yokukhiqiza ezenzakalelayo, okubenza bakwazi ukukhiqiza imikhiqizo ngempumelelo kakhudlwana.

3. Imishini yokuphrinta: Iziqondiso ezinomugqa zingahlinzeka ngokunemba okuphezulu nesilawuli sokunyakaza sesivinini esikhulu semishini yokunyathelisa, okwenza okokusebenza kuphrinte amaphethini amahle kakhulu nombhalo.

4. Imishini ye-elekthronikhi: Iziqondiso ezinomugqa zingahlinzeka ngokunemba okuphezulu nokulawula ukunyakaza okuzinzile kumishini kagesi, okubenza bakwazi ukuhlanganisa nokuhlolwa ngokunembe kakhudlwana.

Isikhathi sokuthumela: Aug-14-2024