Namuhla, i-PYG izochaza ukuhlanzwa nokugcinwa kwesikulufu sebhola. Uma kukhona abantu abasebenzisa isikulufu esihlokweni sethu, sicela ufunde lesi sihloko ngokucophelela. Kuzoba yizimpahla ezomile ezisezingeni eliphezulu ongabelana ngazo.

Isikulufu sebhola sensimbi engagqwali kufanele sisetshenziswe endaweni ehlanzekile, futhi sisetshenziswe kanye nesembozo sothuli, njll., ukugwema uthuli namachips empushana kusikulufa sebhola. Uma uthuli ne-powder kungena ku-screw yebhola ngenxa yokuvimbela uthuli olubi, ngeke nje kukhulise ukwehla komsebenzi we-screw yebhola, kodwa futhi ngezinye izikhathi vimba ngenxa yothuli nezinye izizathu, ukuze izingxenye zokujikeleza zonakaliswe, okuholela ezingozini ezimbi kakhulu ezifana ne-workbench ukuwa.

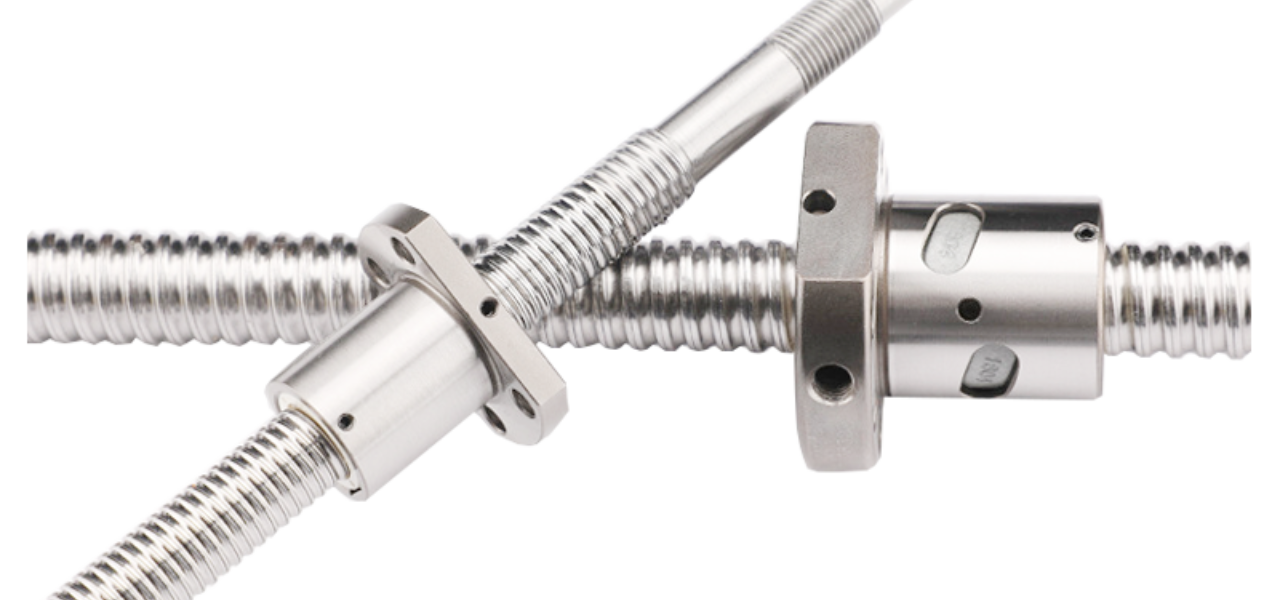

Ukugcinwa kwesikulufu sebhola lensimbi engagqwali:

(1) Ukugcotshwa okungalungile kwesikulufu sebhola kungabangela amaphutha okunyakaza okuhlukahlukene kokuphakelayo kwamathuluzi omshini we-CNC ngasikhathi sinye, ngakho-ke,isikulufu sebholai-lubrication iwukuqukethwe okuyinhloko kokugcinwa kwansuku zonke, futhi ukusetshenziswa kwezinto zokugcoba kungathuthukisa ukumelana nokugqokwa nokusebenza kahle kokudlulisela kwesikulufu sebhola.

(2) Hlola njalo ukuthi ingabe ukuxhumana phakathi kwesikulufu somthofu nombhede kukhululekile, noma ngabe uxhumo lonakele, kanye nesimo sokusebenza kanye ukuthambisaisimo sokusekela isikulufu sokuhola.

(3) Umshini wokuvikela kufanele ugwenywe emsebenzini, futhi umshini wokuvikela kufanele ushintshwe kusenesikhathi uma wonakalisiwe.

Nakuba isikulufu sebhola lensimbi engagqwali sivimbela ukugqwala kwesikulufu ngokwezinga elithile, siyefana nezinye izingxenye zokudlulisa ukungqubuzana okuginqikayo, futhi uthuli oluqinile kufanele lugwenywe phakathi nokusetshenziswa.. Ngakho-ke, ekufakweni, kufanele kube khona idivayisi yokuzivikela.

Eminye imibuzo.ngicelaXhumana nathiukuze uthole imininingwane.

Isikhathi sokuthumela: Nov-20-2023