Inkinga evamile engenzeka ngemihlahlandlela eqondile ePyg namuhla iyanda kakhulu nokungezwani. Qonda izizathu ngemuva kwale nkinga ukuqinisekisa ukusebenza kahle komhlahlandlela oqondile kwemishini.

Esinye sezizathu eziphambili zokwanda kwamandla okudonsela phansi kweI-Linear Motion Guidewaysngiyafunga. Ngokuhamba kwesikhathi, izingxenye zemihlahlandlela eqondile, enjenge-bearings kanye nojantshi, zigqoke ngenxa yokushayisana nokusetshenziswa okuphindaphindiwe. Ngenxa yalokhu, ukungqubuzana okuphelele ohlelweni kuyakhuphuka, okuholela ekucindezelweni okukhulu kanye nemikhosi edonsayo kudingeka ukuhambisa umthwalo.

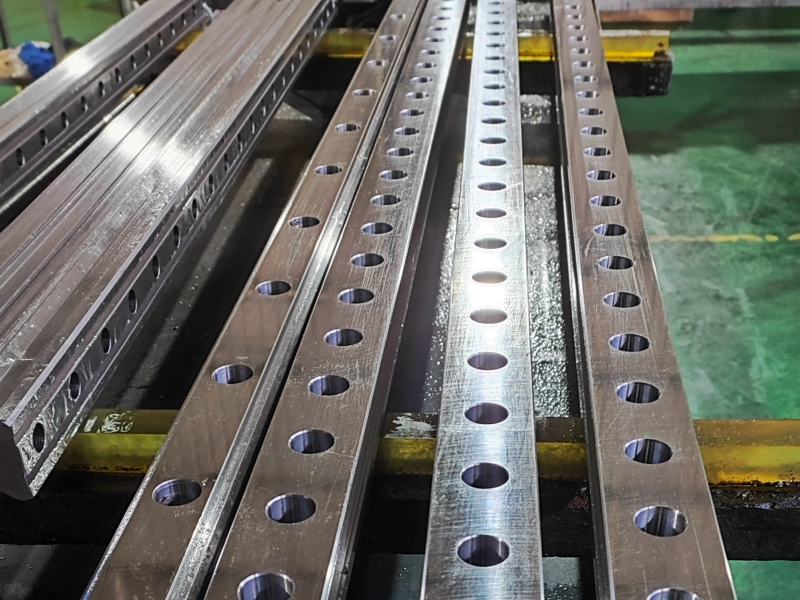

Enye into ebangela ukukhuphuka kwe-push kanye nemikhosi yokudonsa ukungcola. Uthuli, imfucumfucu, nezinye izinto ezingcolile zingangena ezinhlakeni zemihlahlandlela eqondile, okubangela ukungqubuzana nokudonswa. Ukulungiswa njalo nokuhlanza kweIndlela yokuqondisa ye-Linear Izakhi zibalulekile ukuvikela ukwakhiwa kwezingcola futhi kunciphise umthelela ekucindezelweni nasekudonseni amabutho.

Vele, ukuthambisa okungalungile kungaholela ekutheni kuholele ekutheni kwenzeke ngokweqile kanye nokungezwani ohlelweni lomhlahlandlela oqondile. Ukuthambisa okunganele kungaholela ekushayweni okwengeziwe ku-Guide Rail, okuholela ekuphikiseni okwengeziwe ngesikhathi sokunyakaza. Imihlahlandlela yokufutheka yomkhiqizi kumele ilandelwe, futhi izingxenye zokuqondisa eziqondile kufanele zithathwe kahle ukuze zinciphise ukusunduza nokudonsa.

Kwezinye izimo, ukungahambi kahle noma ukufakwa okungafanele kwezingxenye zomhlahlandlela oqondile kungadala futhi ukusunduza ukusunduza kanye nemikhosi yokudonsa. Ujantshi ohlehlisiwe noma ukusatshalaliswa okungekho emthethweni kungadala ukulayisha okungalingani futhi kwandise ukumelana ngesikhathi sokunyakaza. Ukufakwa okufanele nokuqondanisa kweI-CNC emkhakheni weSilayidi Izakhi zibalulekile ukuze zilondoloze ukusebenza kahle futhi zinciphise ukusunduza kanye nokudonsa amabutho.

Ngakho-ke, kuyadingeka ukuqonda izimbangela zokwanda nokungezwani kwezinkomba eziqondile zokuxazulula inkinga nokugcina ukusebenza kahle. Ngokubhekana nezinto ezifana nokugqokwa, ukungcoliswa, ukuthambisa kanye nokuqondanisa, umthelela ekudleni nasekudonseni amabutho angancishiswa ukuqinisekisa ukunyakaza okubushelelezi, okuqondile kohlelo lokuqondisa oluqondile. Vele, uma unemibuzo engacacile, ungakwenzaXhumana nathi, sizophendula umyalezo wakho ngokushesha okukhulu.

Isikhathi Seposi: Jan-16-2024