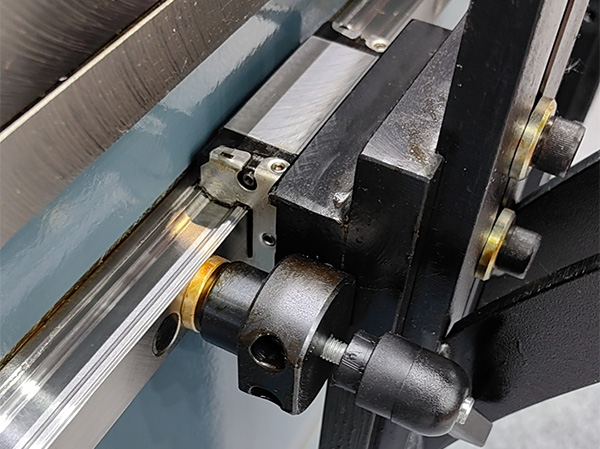

(1) Ukugingqikaumhlahlandlela womugqaipheya ingeyezingxenye zokudlulisela ezinembayo futhi kufanele zigcotshwe. Amafutha okugcoba angenza ungqimba lwefilimu yokugcoba phakathi kwesitimela esiqondisayo nesilayidi, kunciphise ukuthintana okuqondile phakathi kwezinsimbi futhi ngaleyo ndlela kunciphise ukuguga. Ngokunciphisa ukumelana nokungqubuzana, ukulahleka kwamandla okubangelwa ukungqubuzana kungancishiswa, futhi ukusebenza kahle kwemishini kungathuthukiswa. Amafutha okugcoba angadlala indima ekuqhutshweni kokushisa, ukuthumela ukushisa okukhiqizwa ngaphakathi komshini kusuka kumzila wesitimela, ngaleyo ndlela kugcinwe ukusebenza okujwayelekile.izinga lokushisa kwemishini.

(2) Lapho ufaka ipheya yesitimela esiqondisayo emshinini, zama ukungawasusiisilayidikusukela kumzila wesitimela. Lokhu kungenxa yokuthi i-gasket yokuvala phansi ivalwe ngenani elithile lamafutha okugcoba ngemva kokuhlanganiswa. Uma izinto zangaphandle sezixubene, kuba nzima ukwengeza okokugcoba, okuthinta ukusebenza kokugcotshwa komkhiqizo.

(3) Abaqondisi bomugqa bathola ukwelashwa kokuvimbela ukugqwala ngaphambi kokuphuma embonini. Sicela ugqoke amagilavu akhethekile ngesikhathi ufaka futhi usebenzise amafutha angagqwali ngemva kokufakwa. Uma umzila wesitimela ofakwe emshinini ungasetshenzisiwe isikhathi eside, sicela usebenzise njalo amafutha e-anti rust ebusweni besitimela somhlahlandlela, futhi kungcono kakhulu ukunamathisela iphepha le-wax le-industrial anti rust ukuvimbela umzila wesitimela ukuthi ungagqwali lapho uvezwa emoyeni isikhathi eside.

(4) Ngemishini esivele isifakiwe ekukhiqizeni, sicela uhlole njalo izimo zayo zokusebenza. Uma ingekho ifilimu kawoyela emboza ubuso besitimela somhlahlandlela, sicela wengeze ngokushesha uwoyela wokugcoba. Uma ingaphezulu likamzila wesitimela lingcoliswe uthuli nothuli lwensimbi, sicela ulihlanze ngophalafini ngaphambi kokwengeza uwoyela wokugcoba.

(5) Ngenxa yokuhluka kwezinga lokushisa nokugcinwaimvelo ezifundeni ezahlukene, isikhathi sokwelashwa kokuvimbela ukugqwala siyahlukahluka. Ehlobo, umswakama emoyeni uphakeme, ngakho-ke ukugcinwa nokugcinwa kwamareyili okuqondisa kuvame ukwenziwa njalo ezinsukwini ezingu-7 kuya kweziyi-10, kanti ebusika, ukugcinwa nokugcinwa ngokuvamile kwenziwa njalo ezinsukwini ezingu-15.

Isikhathi sokuthumela: Aug-08-2024