Abasebenzisi abaningi abathenge insimbi yomshini wokusika i-laser banake kuphela ukugcinwa kwe-laser kanye nenhloko ye-laser ye-fiber laser metal cutter. Abantu kufanele banake kakhulu ukunakekelwa kwesitimela esiqondisayo.

Yini ama-linear guide rails

Iziqondiso zomugqaabizwa nangokuthi ama-line rails, ama-linear guide rails, nama-linear slide rails. Asetshenziswa ezinhlelweni zokunyakaza eziphindaphindayo ngomugqa. Zinomthwalo onesilinganiso esiphakeme kakhulu kunama-linear bearings. Ngesikhathi esifanayo, bangathwala i-torque eqinisekile futhi bangafinyelela ukunyakaza komugqa we-Precision okuphezulu.

Indlela ama-linear rails asebenza ngayo

Igayidi yomugqa iyithuluzi lokudlulisa ngomshini elakhiwe ngesilayidi kanye aumzila wesitimela. Umgomo wayo wokusebenza usekelwe ekuxhumaneni okuguquguqukayo phakathi kwama-bearings namabhola. Ngokuhlela ama-ball bearings ngaphakathi kwesilayidi kanye nokumisa imigwaqo yomjaho kumzila wesitimela esiwumhlahlandlela, isilayidi singahamba ngokulandelana eduze nomzila wesitimela.

Ngesikhathi sokusebenza, i-amabholanciphisa ukumelana nokungqubuzana ngokuthintana nokugoqa futhi uzuze ukunyakaza okushelelayo kwesilayidi kumzila wesitimela. Indawo yokuxhumana phakathi kwamabhola kanye nomzila womjaho incane, okunciphisa ukulahlekelwa kwamandla futhi kuthuthukise ukusebenza kahle kwesistimu. Umhlahlandlela womugqa ungaphinda ulawule ukumelana nokunyakaza nokuzinza kwesilayidi ngokulungisa amandla okulayisha kuqala ukuze ahlangabezane nezidingo zomsebenzi ezahlukene.

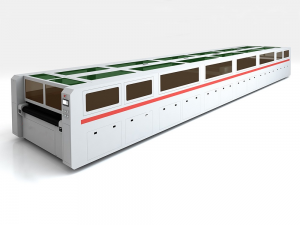

Imisebenzi ye-laser cutting machine linear rail guide

Udlala indima yokuqondisa nokusekela. Ukuze kuqinisekiswe ukuthi umshini unokunemba okuphezulu kokucubungula, imigqa yawo yokuqondisa kanye nemigqa eqondile iyadingeka ukuze ube nokunemba okuphezulu kokuqondisa nokuzinza okuhle kokunyakaza.

Umzila wesitimela uyisiqinisekiso sokunemba kokusika. I-linear guide ujantshi idlala indima eqondisayo nesekelayo emshinini wokusika we-laser. Ukunyakaza okushelelayo kwesitimela somhlahlandlela, kukhuphuka ukunemba kokucubungula komshini wokusika we-laser.

Ikhwalithi yesitimela somhlahlandlelaiyisiqinisekiso sempilo yemishini. Ukufakwa kwesitimela somhlahlandlela kanye nokulungiswa komshini wokusika i-laser kuyinto ebaluleke kakhulu. Ukufakwa nokulungiswa kwesitimela somhlahlandlela womshini wokusika kuzosiza ukuthuthukisa impilo yesevisi kanye nokusika ukunemba komshini wokusika we-laser.

Ukuze wenze umshini usebenze ngokujwayelekile nangokuzinzile, nokuqinisekisa ikhwalithi yokucubungula yensimbi yomshini wokusika i-laser, ukugcinwa kwansuku zonke komzila wesitimela kanye ne-axis eqondile kufanele kwenziwe ngokucophelela.

Isinyathelo 1: Vala amandla e-fiber laser cutter

Isinyathelo sesi-2: Susa isitimela somugqa bese usula ukungcola ebusweni besitimela esiqondisayo ngendwangu eyomile.

Isinyathelo sesi-3: Gcoba igrisi encane emseleni wesitimela somugqa

Isinyathelo sesi-4: Beka amaconsi ambalwa kawoyela wokugcoba ujantshi we-linear guide, bese ubuyisela isitimela somugqa izikhathi eziningana ukuze uqinisekise ukuthi uwoyela wokugcoba ukuyo yonke indawo kumzila wesitimela.

Isinyathelo sesi-5: Faka isitimela somugqa. Bese uvula amandla amakhulu weshidi lensimbi yokusika imishini ye-laser bese ucindezela inkinobho yokusika i-CNC laser yensimbi.

Isikhathi sokuthumela: Apr-02-2024